Rehabilitating maxillectomy defects poses significant challenges that require tailored approaches for each individual patient. To achieve successful outcomes, it is crucial to integrate both traditional and modern treatment methods to enhance the prosthesis’s retention, stability, aesthetics, and functionality. Methods: Three patients with post-COVID Mucormycosis who had undergone localized debridement and partial maxillectomy were treated with a definitive rehabilitation plan. For patients with partial maxillectomy, a cast partial denture designed using Direct Metal Laser Sintering (DMLS) and the altered cast technique was employed. The defect areas were kept as hollow cavities (either closed or open) to reduce the prosthesis’s weight. Results and Conclusion: This approach to prosthodontic rehabilitation proves to be a straightforward and cost-effective treatment, significantly enhancing stomatognathic functions and overall quality of life for patients. Major challenges during rehabilitation include achieving retention and stability due to the absence of basal seat and hard tissue support. To address these challenges, a combination of conventional and digital techniques was utilized to ensure precise fitting and accuracy of the prosthesis, thereby minimizing treatment time and the number of patient visits.

Key words: cast partial denture, mucormycosis, obturator, rehabilitation, altered cast technique

Maxillofacial prostheses aim to restore the

appearance, function, and structure of facial

areas affected by congenital issues, trauma, or

cancer. This specialized field requires extensive

knowledge of dental materials and technologies

to produce long-lasting and effective prostheses.

Following a maxillectomy, which involves the

removal of part of the maxilla, patients face

significant challenges such as difficulties

with oral function, speech, and appearance,

including issues like hyper nasal speech, nasal

regurgitation, and problems with chewing1.

Restoring function with prostheses involves

overcoming challenges such as limited mouth

opening, undercuts in the defect, and obstruction

from the defect’s lateral walls. It’s crucial to

avoid overloading any remaining teeth and to

ensure that the prosthesis remains stable and

functional2. Different obturator designs, including

hollow bulbs and two-piece systems, can affect

the prosthesis’s weight and effectiveness. The

process of prosthetic rehabilitation typically

involves several stages. Initially, a surgical

obturator is used and adjusted to match the

changing defect and surrounding tissues. An

interim obturator assists with oral functions

during the healing phase, until the defect is

stable. Once stabilized, a permanent obturator

is fitted for long-term use3. The prosthesis must

create a secure seal to prevent nasal leakage.

Proper support, retention, and stability are

essential, influenced by factors such as the

defect size, the condition of supporting palatal

shelves, and the state of remaining teeth, which

can act as abutments to improve stability.

Effective

rehabilitation demands thorough

preoperative planning, teamwork between the

surgeon and prosthodontist, and advanced

impression techniques.4 Traditional impression

methods often struggle with these large defects

due to restricted mouth opening and undercuts.

The altered cast technique can address these

issues, enhancing the fit and functionality of

the prosthesis5. This case series focuses on the

prosthodontic rehabilitation and creation of a

hollow bulb obturator for a partially edentulous

patient with an acquired defect, employing

Direct Metal Laser Sintering (DMLS) and the

Altered Cast Technique.

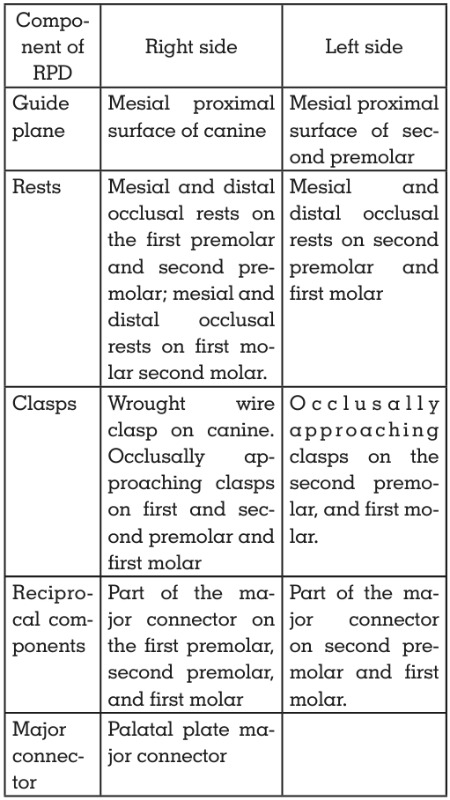

A 70-year-old male with hypertension and non

insulin-dependent diabetes presented to the

Department of Prosthodontics at Government

Dental College, Trivandrum, complaining

about an ill-fitting acrylic maxillary obturator.

The patient reported issues including poor

retention, instability, leakage, and food

accumulation under the obturator, prompting

him to seek a replacement. The patient’s

medical history revealed that he had undergone

a left partial maxillectomy two years ago due

to mucormycosis of the maxilla, which followed

a COVID-19 infection. Extraoral examination

showed facial asymmetry with a collapsed

cheek and a pronounced nasolabial fold on the

left side. Intraoral examination indicated that

the residual maxillary defect had completely

healed. There was visible oro-antral and oro

nasal communication on the left side due to the

partial maxillectomy. Missing teeth included

21, 22, 23, 24, 25, 26, and 27, and the alveolar

ridge was absent with obliteration of the labial

and buccal vestibule on that side. The defect

was classified according to Aramany’s class 1

system. In the mandible, all teeth were vital but

showed generalized physiological attrition.

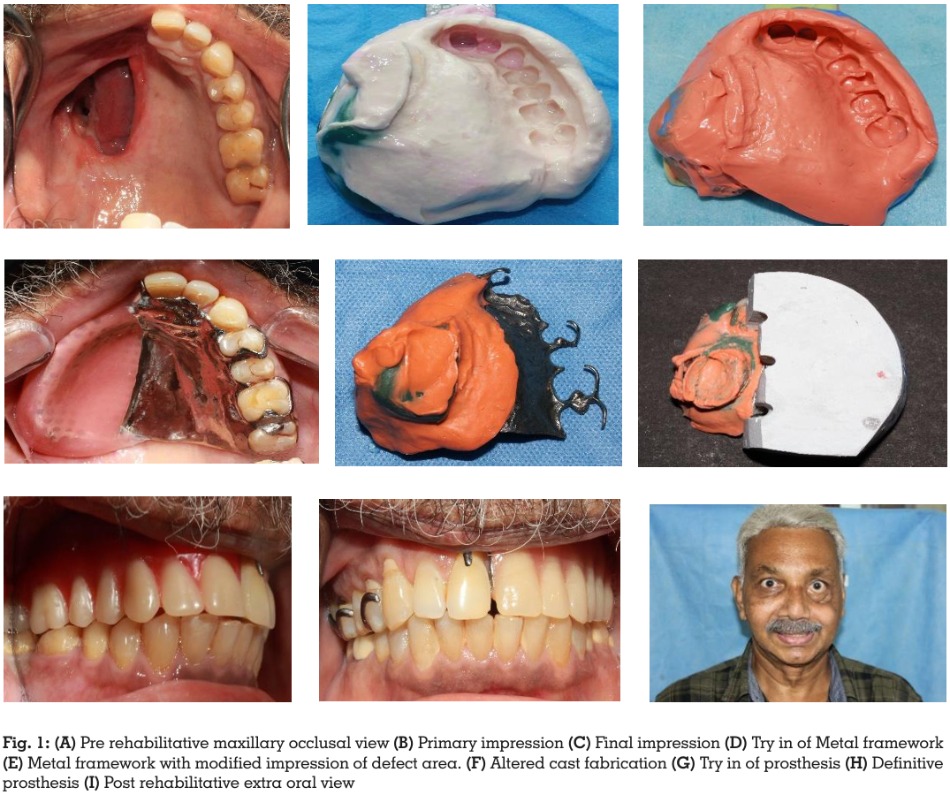

A 38-year-old male patient was referred from the

Regional Cancer Centre, Thiruvananthapuram,

to the Department of Prosthodontics,

Government Dental College, Trivandrum, for

prosthetic rehabilitation of a maxillectomy

defect. The patient had undergone surgical

maxillectomy 8 months back for the treatment

of mucormycosis. The chief complaints reported

by the patient were nasal regurgitation of food

and fluids while eating along with difficulty in

speaking. An extraoral examination revealed

facial asymmetry, with a lack of support for the lips and cheek on the left side. Mouth opening

of the patient appeared normal, with defective

hypernasal speech. The patient was wearing an

ill fitting interim acrylic obturator that required to

be changed. Examination of the interim obturator

found it to be grossly under sized compared to

the defect itself. Intraoral examination revealed

an Aramany type III palatal defect involving

the left side of the arch crossing the midline.

Intraoral examination revealed the presence of

the remaining natural teeth (13,14,16,17,18) in

the maxilla. In the mandible posterior teeth were

missing and maxillary molar was root canal

treated and capped. The osteomucosal-bearing

surface showed a moderate deep palate and

covered with a thick, adherent fibro mucosa. On

the left side, an existing surgical maxillary defect

with adequate healing was noticed in the hard

palate. This defect was connecting the oral cavity

to the left maxillary sinus and the nasal fossae.

It also presented two moderately deep anterior

and posterior undercuts. The radiological

examination panoramic radiography confirms

the existence of the maxillary defect.

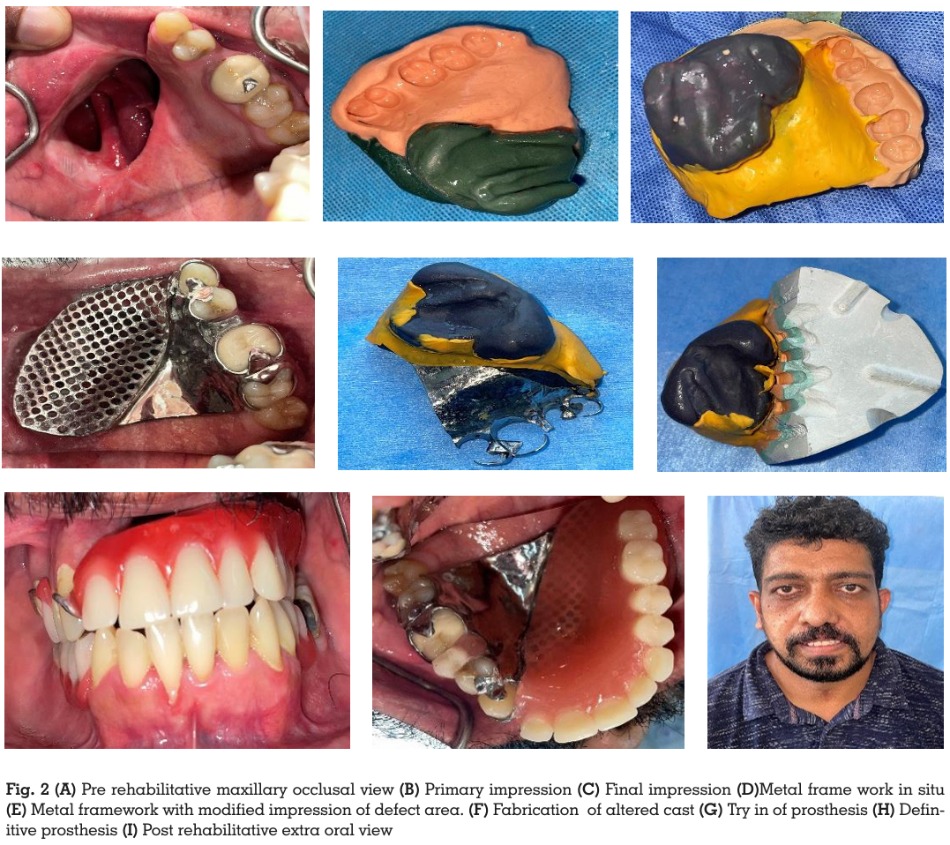

A 45-year-old male patient presented to the

Department of Prosthodontics and Crown &

Bridge at Trivandrum with complaints of missing

teeth, difficulty chewing, drinking, speaking, and

facial deformity resulting from partial maxillary

resection. His medical history was otherwise

unremarkable. The treatment report indicated

that he had undergone resection of the maxillary

ridge, extending from the right lateral incisor to

the left first premolar, 12 months prior due to post

COVID mucormycosis. Extraoral examination

revealed a Class 3 skeletal base with the vertical

dimension preserved. Intraoral examination

showed an Aramany Class VI maxillectomy

defect, resulting in inadequate lip support and a

depressed nasolabial fold. The patient had been initially rehabilitated with an interim obturator

and need to get replaced. All mandibular teeth

were found to be vital.

The patient’s diagnosis includes an acquired

palatal defect resulting from surgical removal

and associated tooth loss. The primary objective

of the treatment was to close the communication

between the oral and nasal cavities with an

obturator, thereby addressing issues related

to speech, swallowing, and deglutition.

Additionally, the treatment aimed to improve

both the aesthetics and functionality of the

patient’s oral cavity.

The proposed treatment plan involved several

steps: providing oral health instructions (OHI),

performing supra- and subgingival scaling

and polishing, offering advice on floss and

interdental brush use, recommending a

fluoridated mouthwash containing 0.05% sodium

fluoride (NaF), and suggesting a toothpaste

with at least 1350 parts per million (ppm) of

fluoride. After these interventions, the plan was

to rehabilitate the patient with a removable

cobalt-chrome partial obturator for the maxilla

using an Altered Cast impression technique and

Direct Metal Laser Sintering (DMLS) fabrication

method, as well as a conventional removable

partial denture (RPD) for the missing teeth in the

mandibular arch.

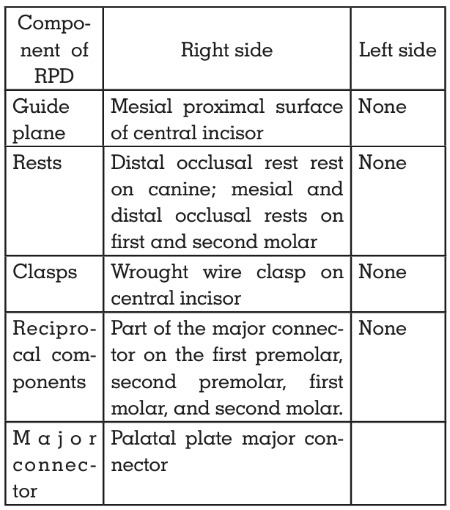

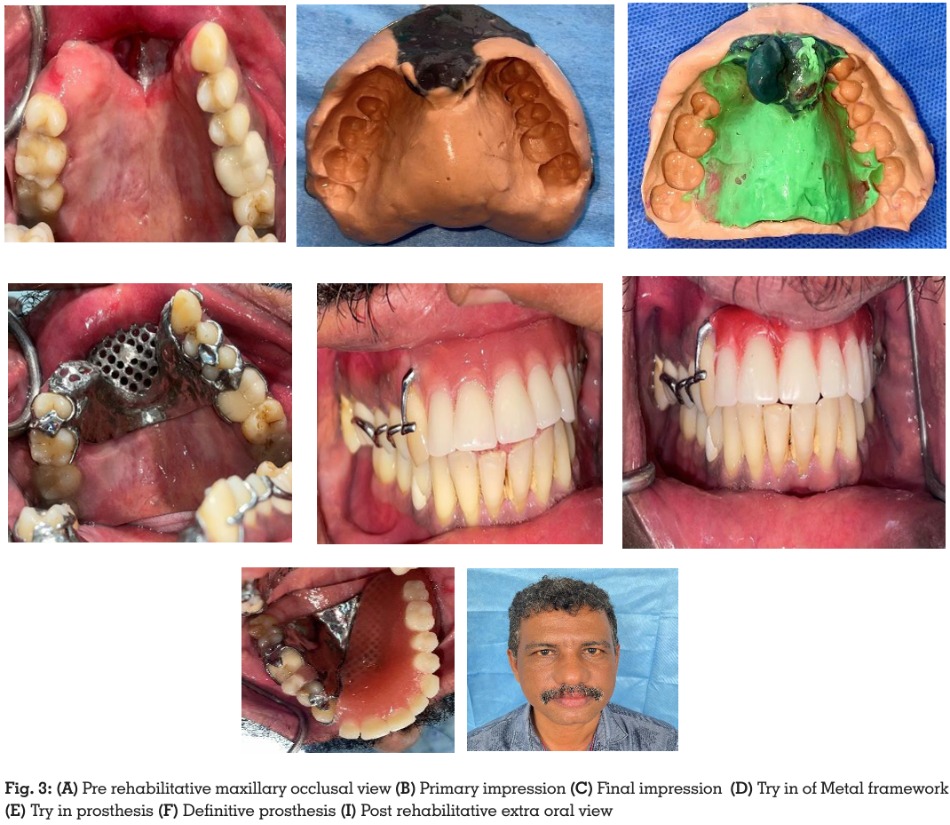

Design for the cobalt-chrome removable partial

obturator (Case report:1)

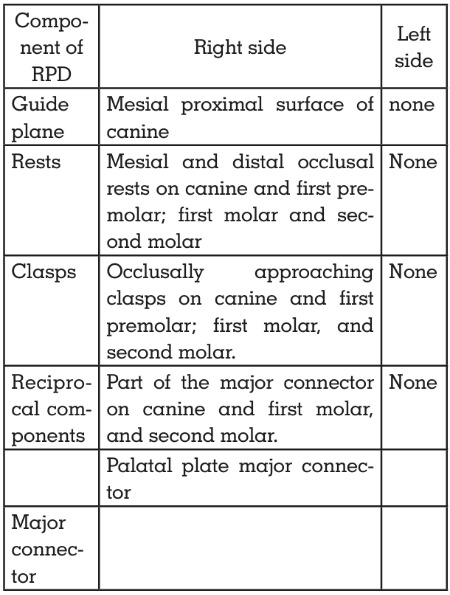

Design for the cobalt-chrome removable partial

obturator (Case report :2)

Design for the cobalt-chrome removable partial

obturator (Case report:3)

In all cases, primary impressions were taken

using conventional impression techniques

since patient’s had normal mouth openings.

Before taking the impression, any undesirable undercuts were blocked with gauze coated in

petroleum jelly to protect the defect area. An

impression was made using irreversible fast

setting hydrocolloid (AlgitexR) after modifying

the upper stock tray for a better fit and blocking

undercuts with the petroleum-laden gauze.

These impressions were then poured with dental

stone type IV (dfine) to create study models.

The maxillary cast was duplicated for future

reference. Then the study casts were carefully

surveyed to design the metal framework.

Considering functional and aesthetic needs,

a removable cobalt-chrome partial obturator

for the maxillary arch was planned. Mouth

preparation involved creating a special tray

using cold-cure acrylic resin (Pyrax Rapid

Repair), performing border molding with green

stick compound (DPIR pinnacle tracing stick),

and taking the final impression with polyvinyl

siloxane (PVS) material ( Perfit elastomeric

impression material). The impression was poured

with extra-hard type IV dental stone (dfine, Type

IV Dental Stone) to obtain the master cast, which was then duplicated to create a refractory cast

from investment material.

The master cast was then scanned using shining

3d Autoscan Ds-Ex C Pro Lab Scanner and the

metal framework was designed using CAD

(EXOCAD) and fabricated with Direct Metal

Laser Sintering (DMLS) technology (EOSINT

M270, Germany), enhancing accuracy and

precision. The fit of the framework was assessed by placing it in the patient’s mouth and using a

pressure indicator paste. The master cast was

modified by slicing it on the defect side, inverting

the metal framework with the defect impression

onto the cast, and pouring after beading and

boxing. Once the cast is set, it was removed to

form the altered cast. A denture base using heat

cure acrylic (Acryton-H) was then made on the

altered cast with the framework in place on the

defect side.

Jaw relations were recorded for centric relation,

and the casts were mounted on an articulator.

Teeth selection and arrangement were

performed, followed by a try-in to check for

retention, stability, function, and aesthetics. The

obturator was made in two parts: the bulb and

the lid. An elastomeric index of the defect area

was created, and a 1.5mm thick thermoplastic

resin sheet (Dentmark) was adapted on both

superior and inferior surfaces to form a hollow bulb. The bulb and lid parts were bonded with

self-cure resin (Pyrax Rapid Repair) to create a

single hollow structure. The obturator’s seal was

tested by immersing it in water.

After successful try-in and hollow bulb fabrication,

flasking and dewaxing were carried out. During

packing, the defect area was first filled with

heat-polymerizing acrylic resin (Acryton-H), and

the previously made hollow thermoplastic body

was adapted over it. The entire area was then loaded with heat-cure acrylic resin and cured.

The prosthesis was finished and polished using

standard methods. The following procedures

were followed in all three case reports.

The final obturator was evaluated for fit,

aesthetics, and function. During insertion,

pressure indicator paste (PIP) was used to detect

any excessive pressure points. The denture

was placed in the patient’s mouth, and care

instructions were provided. The patient was

monitored monthly for the first three months and

then every three months for one year, reporting

satisfaction with the improvements in function,

speech, and aesthetics.

Patients who have undergone maxillectomy

often face ongoing challenges in prosthodontic

treatment, particularly issues with support,

retention, and stability of the prosthetic device.

Factors such as the extent of the defect, the

number of remaining teeth, the condition of

the surrounding bone and mucosa, the effects

of radiation therapy, and the patient’s ability

to adapt to the prosthesis all influence the

success of the treatment6. Preserving as many

of the remaining teeth as possible is crucial

for achieving optimal prosthesis design and

functionality. However, a large, heavy obturator

can put continuous pressure on tissues,

potentially affecting tissue health, function, and

comfort.

Retention of the obturator can be achieved

through several methods, including using

remaining teeth, the ridge, lateral aspects of the

defect, undercuts in soft tissue, and scar tissue.

Stabilization and indirect retention components

must be carefully positioned to prevent movement

of the prosthesis over the defect2.

Implant-supported

fixed prostheses are generally not recommended for these patients

because they require periodic removal and

cleaning, which can be challenging given the

secretions from palatal defect areas. Implant

supported overdentures are a better option

but come with higher costs and the need for a

second surgery7. In such cases, conventional

cast partial dentures are often preferred over

acrylic partial dentures. Cast partial dentures

offer superior accuracy, durability, resistance

to distortion, thermal conductivity, cleanliness,

and reduced bulk. Despite these advantages,

cast partial dentures also have limitations, such

as fabrication difficulties, the need for more

equipment, and potential inaccuracies from

manual casting processes2.

To address these challenges, Additive

Manufacturing (3D printing), particularly Direct

Metal Laser Sintering (DMLS), has gained

significant attention in the dental field. This

technology allows for the creation of metal

based appliances with improved accuracy

and precision. The digital workflow provided

by 3D printing offers many benefits, including

shorter laboratory and clinical treatment

times, optimized production steps, reduced

human error, electronic file transfer and

storage, enhanced accuracy, and better patient

satisfaction. Additionally, it allows for finer

details and more precise anatomical features,

resulting in less material waste8. In the present

case series, the prosthetic rehabilitation of partial

maxillectomy patients were performed using

DMLS-designed cast partial dentures. DMLS

is a fabrication process that builds complex

3D structures directly from CAD designs in thin

layers without additional machining, leading

to improvements in fit, function, and aesthetics.

The use of DMLS and other technologies, such

as milling machines, has been shown to surpass

conventional casting methods in producing

metal denture frameworks5.

Various techniques have been developed for

fabricating removable obturator prostheses,

with the extent of the prosthesis dependent

on the ability to accurately record the defect’s

maximum tissue extent. Accurate impression

techniques are crucial for providing stability.

Techniques such as the two-piece impression

technique, custom adapted trays, and separate

defect impressions have been used, but they

may have limitations related to the integration

of the defect into the denture base. The retention

of obturators relies on engaging remaining

teeth or undercuts in the defect, which obstruct

the removal path, particularly on the defect’s

lateral wall. Recording greater depths in a large

maxillary defect helps create a long lever arm

for increased stability and retention. The two

stage impression technique with an altered cast

technique can help overcome many limitations

of previous methods(7).

Heat-polymerizing acrylic resin is commonly

used due to its ease of manipulation, superior

hygiene, color stability, durability, and tissue

compatibility. It contributes to the lightweight

nature of the prosthesis, which helps in cantilever

mechanics, minimizes soft tissue burden,

and enhances speech resonance. The bulb

component of the obturator is often hollowed

out to reduce weight, which can decrease

the prosthesis’s overall weight by up to 33%,

depending on the defect’s extent9.

The design of the obturator framework should

follow fundamental prosthodontic principles,

including stress distribution over a broad

area, use of a rigid major connector for cross

arch stabilization, and strategic placement

of stabilizing and retaining components to

minimize displacement due to functional forces.

It is essential to wait for the defect site to fully heal

and stabilize before constructing the definitive

obturator, typically between 3 to 6 months post-surgery, depending on various factors such as

tumor prognosis, defect size, healing progress,

and tooth presence3.

Improving the quality of life for hemi maxillectomy

patients is more challenging compared to those

with conventional prostheses. However, with

expertise, knowledge, and experience, specialists

can achieve significant improvements. A team

approach, leveraging skills and experience

at

each stage of treatment, and regular

patient evaluations can effectively address the

challenges faced by hemi maxillectomy patients.

The primary challenge in a maxillectomy patient’s recovery is ensuring adequate retention, stability, and support. A thorough understanding of the patient’s needs and extensive expertise is critical in effectively rehabilitating these individuals(10). The patient’s masticatory abilities, speech intelligibility, and overall quality of life can be significantly improved by designing a definitive obturator prosthesis with maximum coverage and appropriate design.

Conflict of Interests Statement

The authors declare no conflicts of interest.

Consent and Ethical Clearance

As per international standard or university

standard, patient’s written consent has been

collected and preserved.