Aim: To evaluate the accuracy of intaglio surface

of complete dentures fabricated by additive and

subtractive manufacturing methods.

Settings and Design: This was a systematic review

and meta-analysis following the Preferred Reporting

Items for Systematic Reviews and Meta-Analyses

(PRISMA) guidelines.

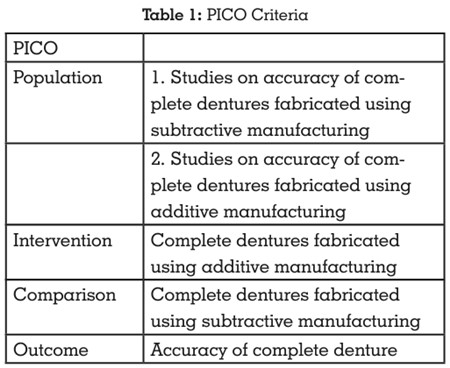

Methods and Material: An electronic search of

PubMed (including MEDLINE), EBSCO host databases,

Cochrane library and Google Scholar search engine

for articles published from January 2011 to Feb 2023

was conducted. The literature search intended to

retrieve all relevant clinical and in vitro studies about

the accuracy of the intaglio surfaces of the complete

dentures fabricated by additive and subtractive

manufacturing methods.

Statistical analysis used: Meta-analysis was

conducted in from the reported quantitative data.

Results: A total of 1468 articles were obtained via electronic search; 10 studies met the inclusion

criteria and were included in this systematic review

out of which 8 were in vitro studies and 2 were

clinical trials. Among the different parameters

described, the accuracy of the intaglio surfaces

of the complete dentures fabricated by different

manufacturing methods were evaluated. Accuracy

was measured by superimposition technique. 8

studies which evaluated the accuracy of the

dentures were included in meta-analysis.

Accuracy between the intaglio surfaces of dentures

showed a statistically significant difference between

milled and 3D printed complete dentures (P < 0.05,

pooled mean difference ranging from -0.13 to 0.18)

Conclusions: There is an overall increased accuracy

in the intaglio surface of the milled complete

dentures when compared to the 3D printed dentures,

thereby making them more preferred.

Key words: Accuracy, complete dentures, CAD CAM, additive manufacturing, subtractive manufacturing

Edentulism can reduce the quality of life

associated with dental health by affecting

appearance, phonation, and function that

can be restored by placing new removable

dentures.1,2 There are numerous techniques by

which a complete denture can be fabricated and

the purposes of each technique are to provide

prosthesis with ultimate mucosal adaptability

and reduce processing error resulting in

good retention, support, and stability. The

clinical protocols involved in the production

of a conventional complete denture may be

complicated, time-consuming, and difficult to

control quality from the laboratory process.3

The adaptation of a removable complete denture

to the underlying soft tissues is important for

retention, masticatory performance, and overall

function.4 Moreover, well-adapted dentures may

reduce trauma to the supporting tissues and thus

minimize bone resorption, avoid the occurrence

of traumatic ulcers, and improve denture wearing

comfort, patient satisfaction, and quality of life.

Thus, the accuracy of the intaglio surface of

removable dentures is key to denture adaptation

and to a successful treatment outcome in

removable prosthodontics. Thus, came into

role the CAD CAM (computer-aided design

and computer-aided manufacturing) complete

dentures which were first described in 1946 and

now represent an improvement over conventional

denture production.5 There are several benefits

of the CAD CAM complete dentures including

reduced chair time, decreased number of patient

visits, simplification of the laboratory process,

produces fewer errors during the denture making

process and can allow the efficient fabrication of

a replacement prostheses i.e., duplicate dentures

based on stored data available. This is highly

helpful for elderly people who have underlying diseases and have difficulty to come to the dental

office.6 The fabrication of complete dentures by

computer-aided design and computer-aided

manufacturing (CAD-CAM) methods has gained

popularity in clinical as well as laboratory

practices.7 There are three processes involved

in the CAD/CAM workflow, the first two steps

being collection of data and CAD. The last step,

CAM process, can be done using either additive

manufacturing (three-dimensional [3D] printing)

or subtractive manufacturing (milling).2

The milling approach is a method of

fabricating dentures by removing materials

from prepolymerized PMMA (Polymethyl

methacrylate) block to form the desirable shape.

Milled dentures possess superior mechanical

qualities over conventional complete dentures

due to the absence of polymerized shrinkage

resulting in better retention.8 Milled maxillary

complete dentures have been reported to be

preferred by both dentists and patients.9 The

principal disadvantage of milling is waste

product, a lot of material remains unused from

the block and thus leads to large amounts of

wastage. Moreover, milling technique has certain

limitations such as the contour of the restoration

relies on the size of cutting tools.2 If the diameter

of the cutting tool is bigger than the diameter

of certain components, the internal fit accuracy

will be compromised, or the marginal qualities

will be degraded. Looking for alternatives that

might solve these problems we came across

3D-printing technique.10 Direct light processing

(DLP) is the most extensively used type of

3D printing in dentistry. Complete dentures

fabricated using the Rapid Prototyping(RP)

technique have also elicited patient satisfaction

comparable with that for conventional complete

dentures.11,12 The purpose of this study is to

evaluate the accuracy of the intaglio surface of the complete dentures fabricated using

subtractive and additive manufacturing. This

systematic review was conducted in accordance

with the Preferred reporting items for systematic

reviews and meta-analyses guidelines 2009 (i.e.,

the PRISMA statement).13

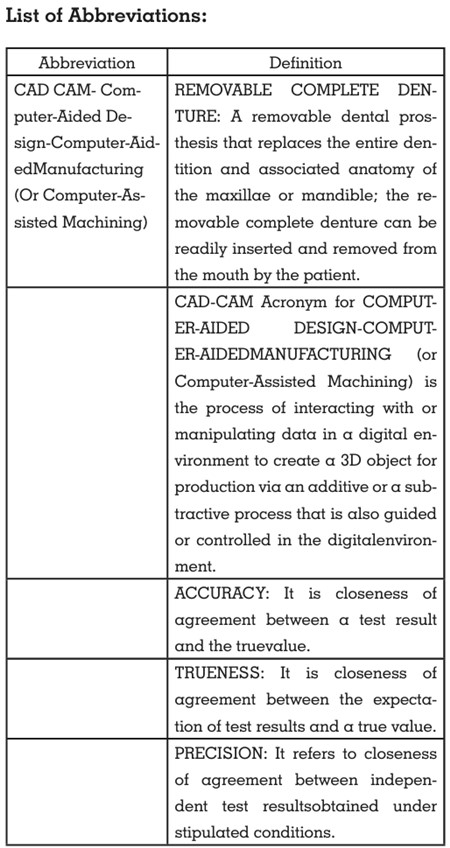

This systematic review was conducted according

to the Preferred Reporting Items for Systematic

Reviews and Meta-Analyses (PRISMA)

guidelines13 with prior registration in PROSPERO

(Registration number CRD42023438705).

The focused question was “Is there a difference

in the accuracy of complete dentures fabricated

by subtractive manufacturing and additive

manufacturing?” The PICO i.e., the Population,

Intervention, Comparison, and Outcome format

was used (Table 1). The inclusion criteria were

studies that evaluated the accuracy of the intaglio

surfaces of the complete dentures fabricated by

additive and subtracting manufacturing methods

and articles appearing in the English dental

literature, published after year 2011 till 28th Feb

2023. The exclusion criteria were studies wherein either of the two manufacturing methods were

not considered. Review articles, case series and

case reports were also excluded.

Electronic search of PubMed (including

MEDLINE), Cochrane Central, EBSCO host

databases and Google Scholar search engine

for articles published from 1st January 2013 to

28th Feb 2023 was conducted. The controlled

vocabulary terms (i.e., MeSH terms) and free text

terms were obtained by searching key concepts

in the MeSH database and a thorough evaluation

of related articles, thesaurus, dictionaries, and

entry terms. The terms such as edentulous

jaws, edentulous mouth, edentulous patients,

fully edentulous arches, completely edentulous

arches, CAD CAM, additive manufacturing, 3D

printing, subtractive manufacturing, milling,

dimensional accuracy, trueness, precision,

surface adaptationwere combined using suitable

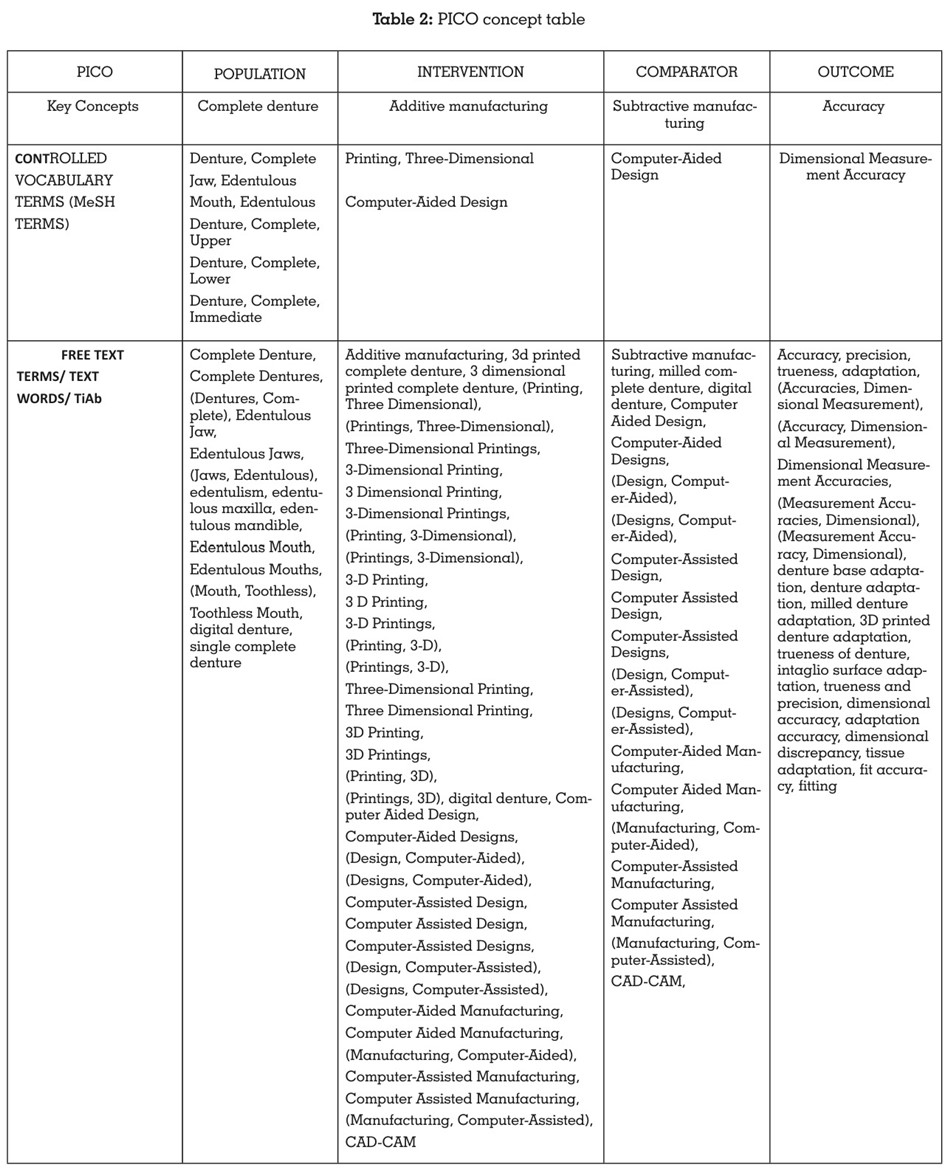

Boolean operators (AND, OR, NOT) (Table 2).

An electronic search was conducted

independently by two reviewers (D.A., S.G.)A

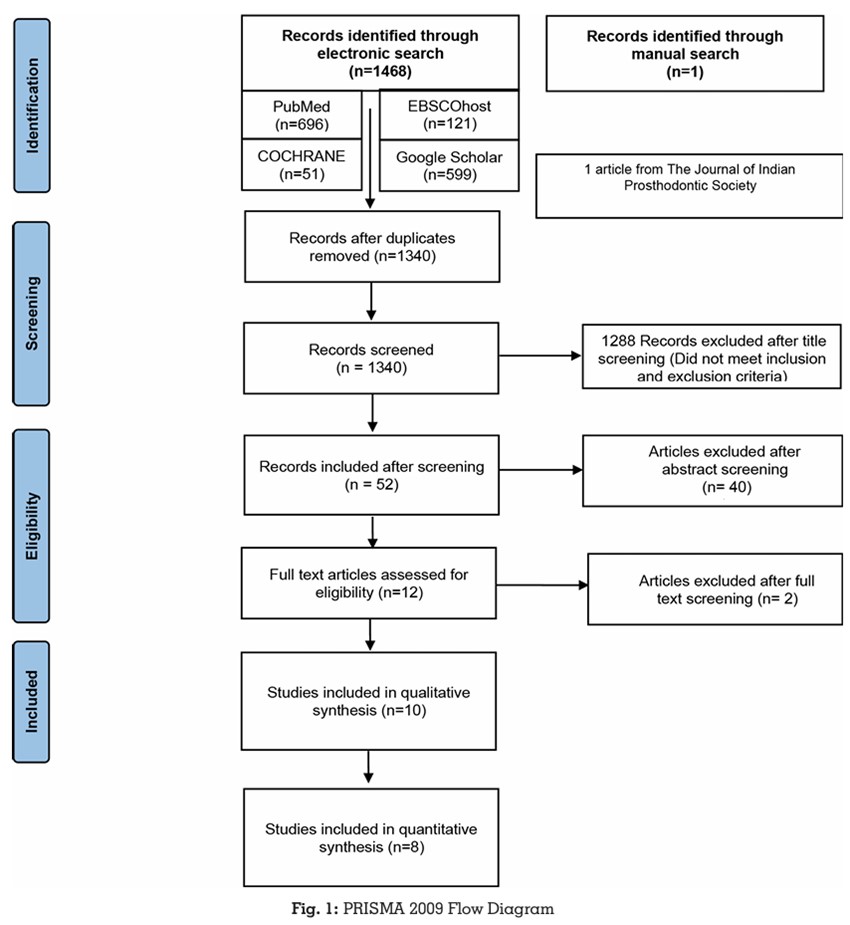

total of 1468 articles were obtained via electronic

search and manual search. The articles thus

obtained were evaluated for duplicates. A

detailed summary of data selection has been

put forth in the PRISMA 2009 Flow Diagram14

(Figure 1).

The study characteristics of each systematic

review were extracted including study details,

search details, analysis, and results/findings by

two independent reviewers (D.A., S.G.)

A third reviewer (P.B.) was called in for a final

decision if any disagreement persisted between

the two calibrated reviewers.

The 1467 articles that were obtained through the electronic searches were compared

meticulously with respect to the author’s name,

year of publication, title, abstract as well as the

journal name, issue, and volume number. The

articles thus obtained after the electronic and

manual searches, were evaluated for duplicates

using the Mendeley Desktop software (v1.19.6).

The 1 article obtained through the manual

search was added manually using the ‘add entry manually’ feature of Mendeley Desktop

software (v1.19.6). The ‘check for duplicates’

feature of this software was then used to identify

and eliminate duplicates. 128 duplicate articles

were identified and subsequently eliminated

leaving behind 1340 articles. Two calibrated

reviewers (D.A, S.G.) independently screened

the relevant titles of the studies found through

the electronic search. Out of 1340 articles, 1288 articles were excluded after screening of the

title. The articles thus eliminated were either

literature reviews, scoping reviews, case reports,

case series, or articles not utilising additive or

subtractive manufacturing for complete denture

fabrication. Thus, 52 articles were selected after

title screening.

Two calibrated reviewers (D.A, S.G.)now

independently screened the abstracts of the

studies found relevant during the screening of

the titles and a total of 40 articles were further

excluded after abstract screening. The articles

eliminated through abstract screening were

mainly involving different manufacturing

methods for the dentures. 12 articles were

included after abstract screening. Out of the 12

articles, 10 met the inclusion criteria and thus were included in this systematic review. Out of

all the included studies, 8 were invitro studies

and 2 were clinical trials.

A third reviewer (P.B.) was called in for a final

decision, if any disagreement over article

selection persisted between the two calibrated

reviewers. Inter-reviewer reliability was checked

via Cohen’s kappa coefficient.15 The Cohen’s

kappa coefficient values obtained for title,

abstract and full text screening was 0.62, 0.68

and 0.75 respectively, indicating moderate inter

reviewer agreement for title, abstract and full

text screening.

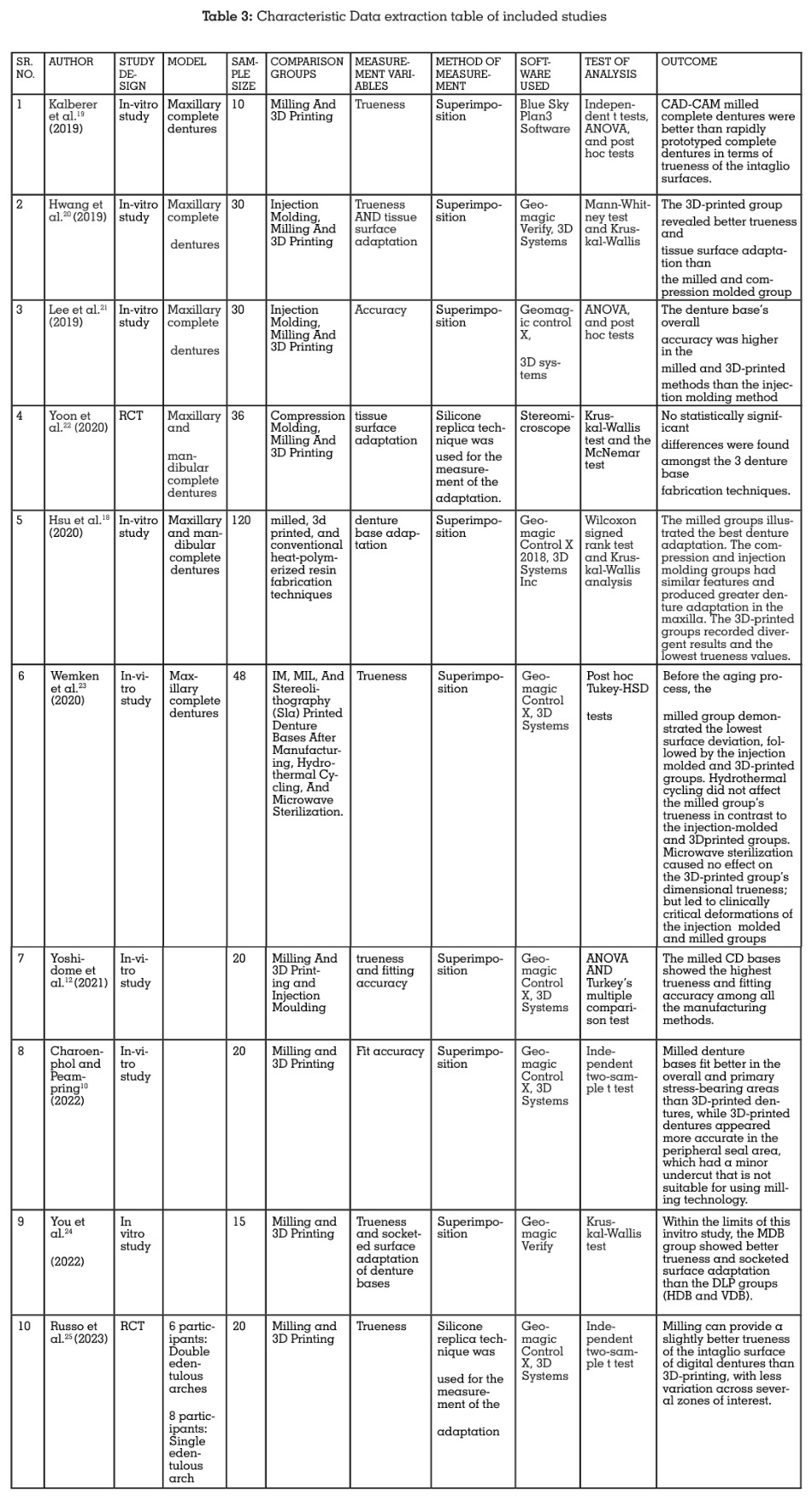

The data was subsequently extracted from the

10 included studies and recorded in 2 excel data

extraction sheets as mentioned in the summary table (Table 3).

The data extracted was entered under the

following headings: Author and Year of

publication, Study design, Study model, Sample

Size, Comparison groups, Measurement

variables, Method of measurement, Software

used, Test of Analysis, Outcome.

Risk of bias assessment of the included studies

was done using the QUIN tool scale16 for in vitro

studies and The Cochrane Collaboration’s tool17

for Randomized controlled trials for RCTs by two

independent reviewers (S.G., D.A.).

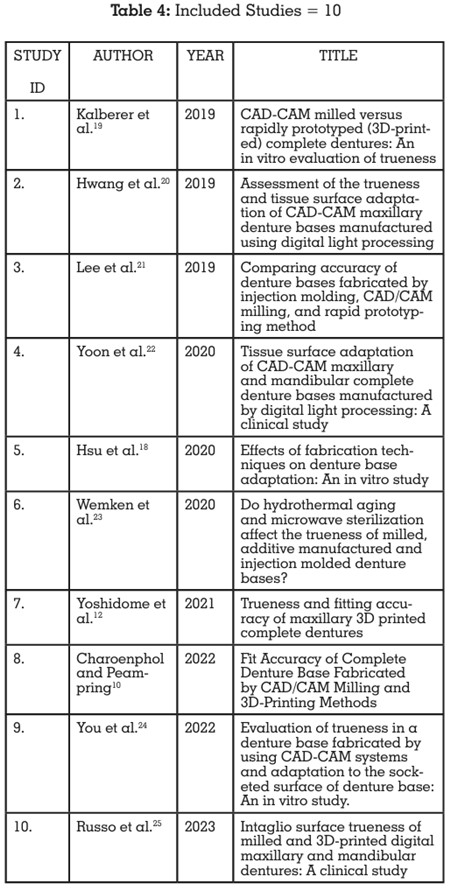

Out of the 10 studies, 8 included studies were

in-vitro studies, hence the Quin tool scale was

considered apt for the risk of bias evaluation

for them in this systematic review. The changes

made to the scale were validated by the third

reviewer (P.B.) (Table 4).

The risk of bias of all the 8 included in vitro

studies ranged from 79% to 87%, which falls

under the category of low risk of bias.

For the 2 excluded clinical studies, The Cochrane

Collaboration’s tool was considered apt (Table

5).

The changes made to the scale were validated

by the third reviewer (P.B.)

10 studies evaluating the accuracy of digital

complete dentures fabricated either by additive

manufacturing or subtractive manufacturing

were included in the systematic review.

Two studies which compared the accuracy of

the intaglio surface of the complete dentures

fabricated either by milling or by 3D printing

(Hsu et al. 2020 and Yoshidome et al. 2021)12,18

were excluded from meta-analysis due to lack of

data availability in terms of mean and standard

deviation values respectively. The eight studies

which evaluated the intaglio surfaces of the

complete dentures fabricated by additive and

subtractive manufacturing (Kalberer et al. 2019,

Hwang et al. 2019, Lee et al. 2019, Yoon et al.

2020, Wemken et al. 2020, Charoenphol and

Peampring 2022, You et al. 2022, Russo et al.

2023)10,19-25 were included for meta-analysis.

The Review Manager software (Version 5.4.1)

was used to perform meta-analysis. Mean

values and standard deviations for accuracy

by assessing surface deviation of dentures

fabricated by milling and 3D printing were

included for the analysis.

The primary outcome measures the accuracy of

the intaglio surface of the complete dentures. The

data was tabulated under the headings of study

name, group, and effect size. The effect size was

calculated on the continuous raw data entered

for mean, standard deviation, and sample size.

95% confidence interval for each effect size was

also computed. The heterogeneity of effects was assessed by the Higgin’s I2 test.26,27 The I2

statistic describes the percentage of variation

across studies that is due to heterogeneity rather

than chance and is denoted by the formula:

I2= 100% x (Q-df)/Q. According to Higgins et

al, calculation of heterogeneity is essential in

determining the generalizability of the findings

of meta-analysis.27

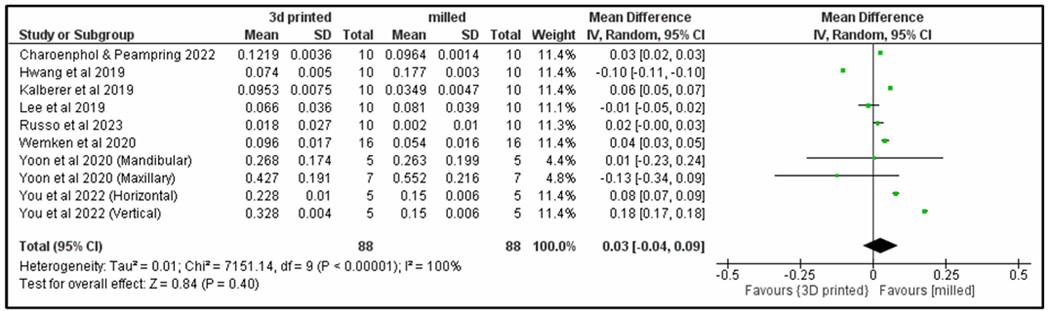

The result of the meta-analysis for accuracy

of CAD CAM complete dentures showed less

surface deviation in milled complete dentures

(subtractive manufacturing) when compared

to 3D printed complete dentures (additive

manufacturing). (Figure 2)

The advent of computer aided designing and

computer aided manufacturing (CAD CAM)

technology has paved the way for a highly precise

and efficient digital work flow.28 There are three

processes involved in the CAD/CAM workflow.

The first two steps in the process are collection of

data and CAM. The last step, CAM process, can

be done using either additive manufacturing

(three-dimensional [3D] printing) or subtractive

manufacturing (milling).29 These two methods

have been considered in this systematic review.

This systematic review has segregated the

accuracy achieved on using additive and

subtractive methods for manufacturing complete

dentures. The two techniques used to assess the

accuracy were superimposition technique for

studies where scanning was performed to attain

impressions and the silicon replica technique

in situations where manual impressions were

made.

Amongst the articles included in this systematic

review, Kalberer et al19 (2019) concluded that

milled complete dentures, under the present

manufacturing standards, were superior to the 3D

printed complete dentures in terms of trueness of

the intaglio surfaces. However, further research

is needed on the biomechanical, clinical, and

patient-centered outcome measures to determine

the true superiority of one technique over the

other about fabricating complete dentures by

CAD-CAM techniques. Hwang et al20 (2019)

conducted an in vitro study and stated that the

3D printed maxillary denture base showed better

trueness and tissue surface adaptation than the

milled and pressed denture bases. The printed

denture bases reproduced the morphologic

irregularity of the residual ridge, while the

milled denture bases had minor inaccuracies.

However, the study design was in vitro and

therefore more clinical evidence is required to

draw any conclusion. Lee et al21 (2019) and Yoon

et al22 (2020) addressed that both 3D printed and

milled denture bases were likely to show intimate

adaptation compared with other techniques.

Both the studies showed no significant

differences amongst both the groups. Hsu et

al18(2020) concluded that the milling technique

had the best denture adaptation, whether

using the silicone thickness measurement

or digital superimposition analysis. Milling

technique improves the adaptation whether for

maxillary or mandibular denture bases, but the

printing technique presents divergent accuracy. Wemken et al23 (2020) concluded that subtractive

manufacturing of denture bases results in the

highest trueness, followed by injection moulding

and 3D printing. The author also subjected the

dentures to hydrothermal cycling and microwave

sterilization. In contrast to injection moulding

and 3D printing, hydrothermal cycling did not

affect milled denture bases. However solely SLA

printed denture bases remained dimensionally

stable after microwave sterilization. In a clinical

study conducted by Russo et al25 (2023), within

the limits of the manufacturing methodologies

used for complete dentures, milling provided

better trueness of the intaglio surface when

compared to 3D printed dentures. The in vitro

studies conducted by Yoshidome et al12 (2021),

Charoenphol and Peampring10 (2022) and You

et al24 (2022) concluded that milled complete

denture bases showed the highest trueness and

fitting accuracy among all the manufacturing

methods. Thus, a systematic review compiling the

conclusions of these in vitro and clinical studies

was conducted to draw a conclusion regarding

the improved accuracy of complete dentures

when fabricated by different methodologies i.e.,

additive, and subtractive manufacturing.

The Quin tool16 for invitro studies and Cochrane

tool17 for RCTs has been used to identify the risk

of bias of the individual studies.

Eight out of the 10 included studies seemed to be

relatively homogenous in their study design and

outcome variables. Hence, a quantitative analysis

by means of a meta-analysis was planned. Meta

analysis is a systematic procedure for assessing

and combining statistical information based

on results of available independent studies

regarding the same topic.30 The results of the

quantitative analysis have been provided in the

form of forest plots for easy visualization.

The heterogeneity of the primary studies has been evaluated using the Higgins’s I2 test.11

Heterogeneity refers to differences in results

between primary studies that are greater than

expected by chance alone.

The result of the meta-analysis for accuracy

based on surface deviation showed less accuracy

for 3D printed dentures compared to the milled

complete dentures.

Limitations of this systematic review were; The

search for this study was limited to articles

published in the English language. Also, grey

literature has not been searched for relevant

literature. This could have resulted in mild

selection bias.

The results of this systematic review should be

applied with caution to the clinical scenario

since most of the included studies are in-vitro in

their study design.

Within the limitations of this systematic review and meta-analysis, the following conclusions could be drawn: