Purpose: To evaluate the effect of adding 1wt% of

Al2O3, SiO2, and ZrO2

nanoparticles to heat cure

acrylic resins on their flexural strength.

Materials and Methods: PMMA is the widely

accepted denture base material but has got the

disadvantage of low mechanical strength. So

the study evaluates whether reinforcement with

nanoparticles improves its flexural strength. A total

of 88 specimens are prepared in 4 groups (Control,

1wt% Al2O3, 1wt% SiO2, 1wt% ZrO2) and 3 subgroups

(5 nm & 15 nm of all Nano groups) (n =22/group). The

PMMA powder and nanoparticles are mixed with

each other by means of ball milling and is invested

in type III dental stone for processing. Flexural

strength is measured via three-point bending

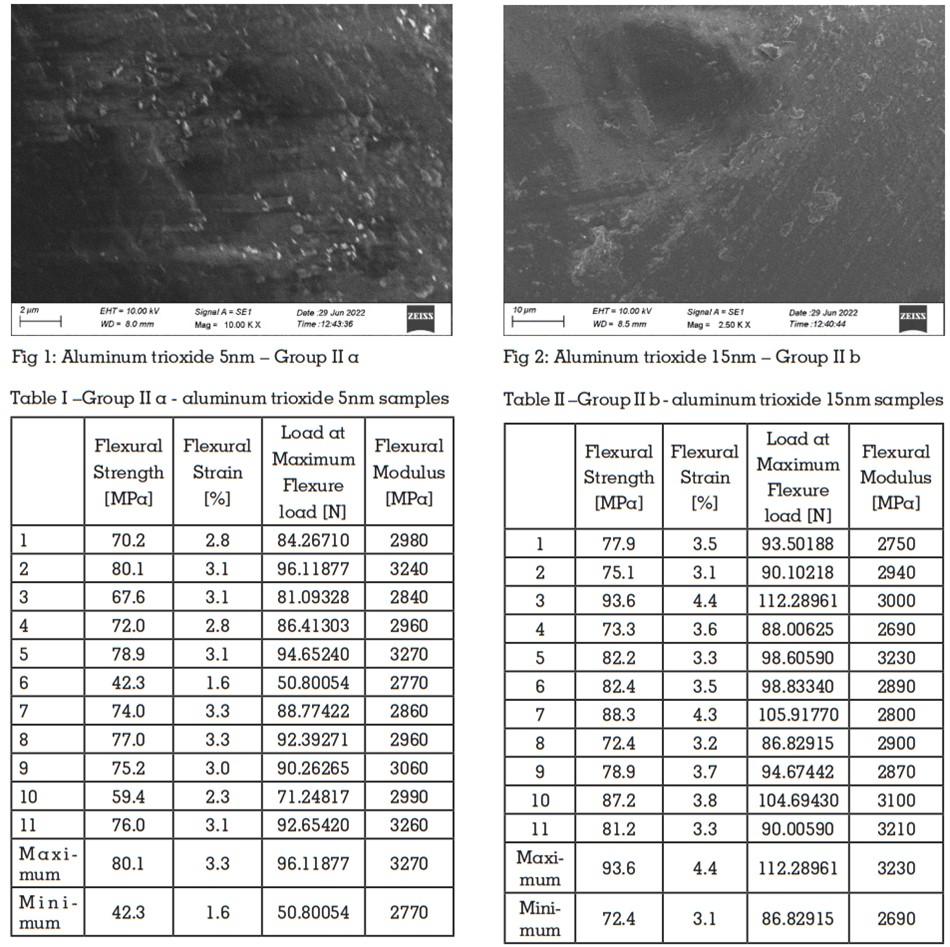

tests. Subsequently, SEM analysis is performed for

specimens from each group to ensure homogenous

distribution.

Results: The flexural strength of

polymethylmethacrylate (PMMA) after adding 1wt%

of aluminium trioxide 15nm significantly increased

(p ˂ 0.05) followed by 1wt% of silicon dioxide 15nm.

The scanning electron microscopy analysis revealed that the particles were homogeneously dispersed

in PMMA matrix.

Conclusion: The mechanical properties of heat cure

PMMA can be increased by addition of nanoparticles

to PMMA powder. 1wt% of aluminum trioxide-15nm

diameter has significantly improved the flexural

strength of PMMA.

Key words: nanoparticles, Flexural strength, Aluminum trioxide, Zirconium dioxide, Silicon dioxide.

Denture base is defined as the part of a denture

that rests on foundation tissue to which the teeth

are attached. The denture base material is

defined as any substance of which the denture

can be made. -GPT9

Poly (methyl methacrylate), is widely used in

rehabilitation of edentulous patients because of

its satisfactory esthetics, ease of use, low cost,

light weight and stability in the mouth5,8. Many

different materials such as bone, wood, ivory, vulcanized rubber, polystyrene, light activated

UDMA are used but PMMA remains preferred.

But the material has the disadvantage of low

mechanical properties such as low flexural

strength and impact strength resulting in fracture

of the denture when subjected to occlusal flexural

strength of standard denture base polymers

prescribed is 65 MPa by the ISO 1567.

Nanoparticles are effective reinforcing materials

and used as fillers for polymeric materials

to improve their mechanical properties. They

are characterized by their smaller size, larger

specific surface area, and also strong interfacial

interaction with organic polymers. The dimension

of the material is in nanometer, which leads to

unique properties. In the current study 1wt% of Al2O3, SiO2, & ZrO2 of diameter 5nm and 15nm

are added to improve the mechanical properties.

The purpose of the study is to evaluate the flexural strength of heat cure PMMA on adding 1wt% of Al2O3, SiO2, & ZrO2

of diameter 5nm and 15nm.

Polymer is a macromolecule composed with

repeated unit. They are formed by condensation

polymerization or addition polymerization.

Acrylic resins are polymer esters of methacrylic

acids. PMMA is the combination of methyl

methacrylate with chemical formula (C5H8O2) n.

PMMA is a linear thermoplastic polymer which

lack of methyl group on its backbone carbon

chain.

PMMA is commonly used denture base material. The PMMA employed in the current study is

IVOCLAR Vivadent SR triplex hot pink heat cure

veined denture base material. The powder liquid

ratio is followed according to the manufacturer’s

instruction as 20 ml for 43.8 gm. of powder by

means of measuring jar and graduated cylinder.

The specimens of the dimension 65mm in length,

10mm wide and 3 mm thickness are fabricated as per the ISO 1567 standard, by using templates.

In the present study, three different nanoparticles

were added in ratio of weight 1 wt% nanoparticles (Al2O3, ZrO2, SiO2) to the heat cure acrylic

resin. 1wt% nanoparticles (Al2O3, ZrO2, SiO2) has

been used so as to prevent agglomeration and

to ensure homogenous distribution without adversely affecting the mechanical properties.

These were categorized into the following

4 groups pure PMMA – Group I, PMMA with 1wt%

Al2O3

-Group II, PMMA with 1wt% SiO2

– Group

III, PMMA with 1wt% ZrO2

– Group IV and 3 sub-groups PMMA with 5nm 1wt% Al2O3

(Sub Group

II a) & 15 nm 1wt% Al2O3

(Sub Group II b), PMMA

with 5nm 1wt% SiO2 (Sub Group III a) & 15nm

1wt% SiO2

(Sub Group III b), PMMA with 5nm

1wt% ZrO2

(Sub Group IV a) & 15 nm 1wt% ZrO2

(Sub Group IV b).

The investment is made using type III gypsum

product. The PMMA powder and Nano particles

are mixed by means of ball milling machine

(RETSCH PM 100). The speed is set at 350 rpm

for one hour with four steel balls of diameter

10mm with an interval at 30 minutes.

The PMMA powder (IVOCLAR Vivadent SR

Triplex Hot) along with the nanoparticles (Matrix

Nano) is mixed with the liquid (monomer) and

left for 10 minutes and then packed into the flask.

The flask is approximated and kept for curing in

the curing unit (DELTA – Tempsen Polybath) for

two hours and then boiled for 1 hour. The flasks

were allowed to cool for 30 minutes and placed

under running water for 20 minutes to ensure

complete cooling. Then the specimens were

deflasked, trimmed and polished using 200, 400

and 600 grit sand paper and the specimens are

immersed in distilled water. The samples are

then subjected to three-point bending test using

universal testing machine (INSTRON 3345 –

Bluehill 3). After being subjected to three-point

bending tests the specimens are analyzed under

scanning electron microscope (CAREL ZEISS EVO18) to ensure homogenous distribution of

nanoparticles.

The data was expressed in mean and standard

deviation. Statistical Package for Social Sciences (SPSS 20.0) version used for analysis. Oneway ANOVA (Post hoc) followed by sh used for

analysis. p value less than (p<0.05) considered

statistically significant at 95% confidence

interval.

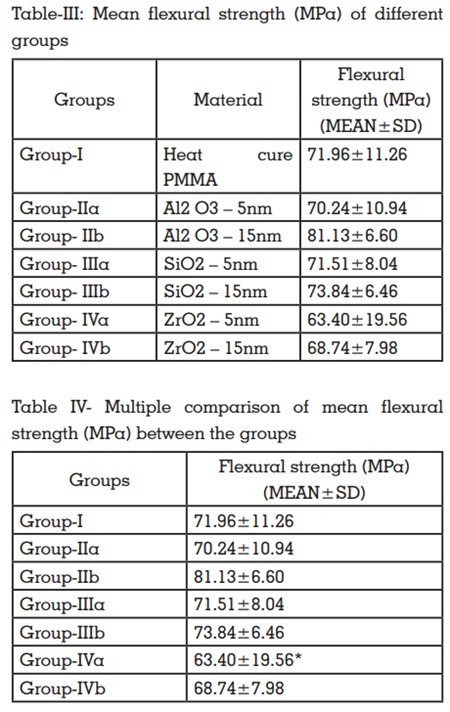

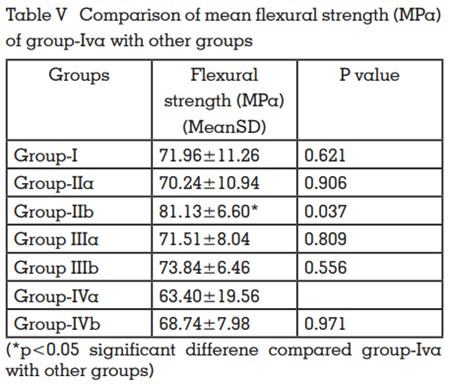

The values of control group exhibit a maximum

flexural strength value of 94.3 MPa and a

minimum of 55.8 MPa with an average mean of

71.96 ± 11.26 MPa.

The flexural strength of heat cure PMMA reinforced with 1wt% of 15 nm aluminum trioxide

(81.13 ± 6.60 MPa) (table III) exceeded those of

other groups followed by 1wt% of 15nm Silicon

dioxide (73.84 ± 6.46 MPa) (table III) and the

group reinforced with 1wt% of 5 nm Zirconium

dioxide (63.40 ± 19.56 MPa) (table III) had the

least strength. The values of 15nm Al2O3

and

15nm SiO2

were found to be statistically significantly higher than those of the control group (p

< 0.05).

PMMA is commonly used material for denture

base because of its ease of use, polishability

and light weight. But it has got the disadvantage

of low flexural strength and impact strength resulting in the fracture of denture. Reinforcement

with nanoparticles is expected to improve the

mechanical properties.

The present study evaluated the flexural strength

of heat cure PMMA reinforced with different nano

particles and sizes. Different nanoparticles, such

as aluminum trioxide, silicon dioxide, zirconium

dioxide of 5nm and 15nm diameter were used.

According to the study conducted by Karci et

al34 particles of size as low as 15 nm produced

better results so in the current study comparison

between 5nm and 15 nm were done to test the efficacy. The mean flexural strength of the control

group obtained is -GROUP I- 71.96 ± 11.26 MPa.

The mean flexural strength of other groups when

compared to the control group clearly states that

group IIb (81.13 ± 6.60 MPa) (table III) has the

highest values followed by Group IIIb (73.84 ±

6.46 MPa) (table III). Group IVa has got the lowest strength (63.40 ± 19.56 MPa) (Table III)

The minimum value of flexural strength of standard denture base polymers prescribed is 65

MPa by the ISO 1567. The values (table III) of

Group IIa (70.24 ± 10.94 MPa), IIb (81.13 ± 6.60

MPa), IIIa (71.51 ± 8.04 MPa), IIIb (73.84 ± 6.46

MPa), IVb (68.74 ±7.98 MPa) and control - group

I (71.96 ± 11.26 MPa) satisfies this requirement.

The values of group IVa - zirconium dioxide 5nm

(63.40 ± 19.56 MPa) is less than that of the ISO

1567 requirement. On comparing mean flexural strength of aluminum trioxide 5nm (70.24 ±

10.94 MPa), silicon dioxide 5nm (71.51 ±8.04

MPa) and Zirconium Dioxide 5nm (63.40 ±19.56

MPa) the silicon dioxide 5nm had the highest

mean flexural strength. On comparing mean

flexural strength of aluminum trioxide 15nm

(81.13 ± 6.60 MPa), with silicon dioxide 15nm

(73.84 ± 6.46 MPa) and Zirconium Dioxide 15nm

(68.74 ± 7.98 MPa) the aluminum trioxide 15nm

(81.13 ± 6.60 MPa) had the highest mean flexural strength (Table IV).

On comparing mean flexural strength of aluminum trioxide 5nm (70.24 ± 10.94 MPa) and 15nm

(81.13 ± 6.60 MPa) no significant difference was

observed. The p value is 0.502 (P>0.05).On comparing mean flexural strength of Silicon Dioxide

5nm (71.51 ± 8.04 MPa) and 15nm (73.84 ± 6.46

MPa) no significant difference was observed. The

p value is 1.00 (P>0.05). On comparing mean flexural strength of Zirconium Dioxide 5nm (63.40 ±

19.56 MPa) and 15nm (68.74 ± 7.98 MPa) no significant difference were observed. The p value is

0.971 (P>0.05). On comparing the mean flexural

strength of Group IIa with other groups no significant difference were observed (p>0.05). On

comparing the mean flexural strength of Group

IIb and Group IVb with other groups significant

difference were observed (p<0.05). On comparing the mean flexural strength of Group IIIa and

Group IIIb with other groups no significant difference were observed (p>0.05). On comparing

the mean flexural strength of Group IVa with other groups significant difference were observed

(p<0.05) (Table V).

Multiple comparison of mean flexural strength

(MPa) between the groups states there is significant difference on comparing Group III a with

Group IVa. (p<0.05). In accordance with the

study conducted by Unal et al39 the shape and

size of the filler particles, distribution in the polymer matrix, and connection to the matrix play a

very important role, and also the size of metal

oxides should be sufficiently low for homogenous mixtures. This prevents a heterogeneous

mixture, and nanoparticles will fill in the cracks

between polymer matrix, thereby preventing the

movement of the chain. In addition to that, the

percentage of the nanoparticles should be kept

low so that the particles will be embedded in the

resin without agglomeration. Balos et al23 also

concluded that low concentration provides better properties.

According to the study conducted by Mahroo

et al49 2.5 wt% of aluminum trioxide with grain

size of 3 micrometer significantly increased the

flexural strength. The addition of 5 wt% Al2O3

powder caused a 5.82% reduction in flexural

strength. Possible explanations for this decrease

in strength could be a decrease in cross-section

of the load-bearing matrix of polymer; stress

concentration due to too many filler particles;

mode of crack propagation through the specimen because of increased amount of fillers; void

formation from the entrapped air and moisture;

incomplete wetting of fillers by resin; and acts as

an interfering factor in the integrity of the polymer matrix. In this study, 1wt% has been used so

as to prevent agglomeration and to ensure homogenous distribution without adversely affecting the mechanical properties.

According to the study conducted by Neveen et

al11 High Impact acrylic resins reinforced with

5% and 15% ZrO2

showed that it increased flexural strength and the flexural strength was proportional to the concentrations. In contrast to this, Ihab and Moudhaffar28 compared the flexural strength after adding ZrO2

nanoparticles

and stated a statistically significant reduction of

more than 5%. So addition of nanoparticles can

influence the flexural strength both in a positive

as well as negative aspect.

According to the study conducted by Reem

Abualsaud, the Nano SiO2

particles increased

the flexural strength. Additionally silane treatment of the nanoparticles enabled stronger

bonds with the matrix.

In the current study highest values are obtained by using 15nm Aluminum trioxide

(81.13±6.60 MPa) followed by 15nm silicon dioxide (73.84±6.46MPa) (table III). The p value

is significant for the 15nm 1wt% Al2O3

(p<0.05).

The zirconium dioxide 5 nm had the lowest value (63.40±19.56 MPa) with a significant p value

(p<0.05).

On comparing the diameter among the same

groups no statistically significant results were

obtained (p>0.05) but still 15nm sub-groups

of all the three major groups had better results

when compared to the 5nm sub-groups (Table

I and Table II). In the study conducted by Karci et al34 the specimens after testing for flexural strength are then subjected to SEM analysis

to ensure homogenous distribution. Similarly in

the present study, specimens after three point

bending test were analysed under SEM for ensuring homogenous distribution. (Fig. 1 and Fig.

2). This homogenous distribution as stated by

Karci et al34 has promoted the mechanical properties of the material. A few studies recommend

using coupling agents to prevent the agglomeration of particles. They have also stated that

the well-distributed particles are only capable of

better stress transfer and reinforcement. The null

hypothesis was rejected, as the flexural strength

has changed after the addition of nanoparticles.

The flexural strength of heat cure PMMA reinforced with 1wt% of 15 nm aluminum trioxide exceeded those of other groups followed by 1wt%

of 15nm Silicon dioxide and the group reinforced

with 1wt% of 5 nm Zirconium dioxide had the

least strength.

Variations in the particle size were found to be

effective in improving the strength. According

to the study conducted by Karci et al34 the nano

particles of diameter as low as 15 nm were yielding a good improvement. In the current study

comparison between 5nm and 15nm was done

to evaluate whether 5nm diameter particles provided better results. The results do not show statistically significant results but 15nm groups had

better results compared to the 5nm sub groups.

In the present study, the saliva was not considered since this study was an in-vitro study,

whether it might affect the results clinically is not

evident. Furthermore, the leaching of particles

might vary the biological properties of heat activated denture base material. This has proven to

be a major limitation of the study and thence an

in-vivo study can be considered in the near future. The optical properties of aluminum trioxide

were not that satisfactory as it caused greyish

discoloration. Henceforth, efforts have to be undertaken for improving the optical properties of

aluminum trioxide nanoparticles.

Reinforcing PMMA with the nanoparticles such as aluminum trioxide, silicon dioxide and zirconium dioxide has proved to be beneficial in improving the mechanical properties. The flexural strength has been increased on addition of these particles. Adding nanoparticles can adversely affect the mechanical properties also. It is observed that Lower concentrations of nanoparticles prevents agglomeration and have better results. Concentration as low as 1wt% has yielded positive results. The Particle size also plays a vital role in ensuring reinforcement. Particle size of about 15nm has yielded better results. The following conclusions can be drawn from this study