Digitalised prosthetic rehabilitation modalities are becoming an essential approach for maxillofacial prosthetic field in present era. As technologies like nanotechnology, biotechnology, informatics, and cognitivism improve, maxillofacial amplification prostheses can now operate instinctively rather than passively. Through hybridization and the establishment of a genuine neurophysiological link with the environment, these can make maxillofacial amplification prostheses a reality. This narrative review emphasizes numerous technological advances in the field of maxillofacial rehabilitation, which, by resolving graft rejection and minimizing donor site morbidity, may pave the way for new avenues in reconstructive surgery.

Key words: Maxillofacial rehabilitation, 3D printing, trends, technologies

Maxillofacial deformity can result from malignancy, developmental trauma, or genetic flaws

that impair function and appearance, making

it difficult to lead a regular social life. Rehabilitating patients with craniofacial deformities has

historically been a difficult task due to the extended procedures and multiple clinical visits

needed for the fabrication of maxillofacial prostheses. People have been able to get beyond

these restrictions to some extent because to the

usage of cutting-edge materials and technology1-3. The industry has undergone a revolution in

digital technology, which have made the process

of designing, producing, assessing, and visualizing prostheses more efficient. The convergence

of technologies such as nanotechnology, biotechnology, informatics, and cognitivism (NBIC)

has made it possible for prostheses to introduce

new extrasensory capabilities and facilitate

authentic neurophysiological interactions with

their users. The biotechnological future of maxillofacial rehabilitation incorporating augmented reality with bioprinting along with 3D scanning

can make a patient experience new level of reality and comfort.

Maxillofacial prosthetics (MP) has long been

driven primarily by its strong association with

maxillofacial surgery. The field of maxillofacial

rehabilitation has historically been directed

by surgical considerations, and maxillofacial

prosthesis is a dependable and complementing option that fills in the gaps and resolves the

shortcomings that surgery alone cannot1. However, the field of maxillofacial rehabilitation is

changing as a result of the rapid development of

new technologies. This evolution is progressing

from simple repair to more advanced methods

that prioritize regeneration. As these technologies advance, they have the potential to improve

treatment outcomes and better satisfy patients

demands for all-encompassing, conclusive solutions to their maxillofacial problems2

Combining the terms cybernetic and organism,

neurophysiologist Manfred Clynes coined the

term “cyborg” in 1960 to denote a person who enhances or benefits from artificial means in their

biological functioning and was reintroduced

into the scientific literature following the work of

Donna Harway in its cyborg manifesto4

. These

techniques modifies the body biochemically or

electronically. Jean Claude Heudin proposed an

extensive classification of cybernetic phenotypes

from robots to avatars5

. Robotic and biological

cybornetic organisms are the two subcategories of cyborgs. Robotic Cybornetic organisms

are groups of organic molecules (e.g., the Terminator) on artificial structures that eventually

become humanoids which exist in science fiction

only. Conversely, those with sophisticated prostheses (robocops) are considered biological cyborgs and are already a part of our environment.

AR finds application in managing visual impairments like low vision, color vision deficiencies,

blindness, and visual field defects (Amblyopia,

Nyctalopia, and Metamorphopsia) HMD-based

AR systems and smartphone-based AR systems

are the two main types of AR prototypes. HMD based augmented reality systems comprise both

home-built and commercially produced AR systems, such as those made by Google and Microsoft. Google Glass is a wearable computing

device with an optical head-mounted projection

which works by combining both augmented and

virtual reality. Google introduced it in April 2012,

and the Google X lab developed to work based

on the Android operating system6.

Google Glass is built in with tiny chips that house a speaker, battery, video display, and camera. It has an Android-powered hands-free display and can establish Wi-Fi and Bluetooth connections with a phone. To record pictures and scenes that are within the wearer’s field of vision, tiny camera chips are used. On the video display, information is provided in a pop-up manner for hands-free viewing.

One of the major concerns of Google Glasses

is the possibility of privacy violations regarding

the user. Being expensive, only surgeons, military, astronauts, and elite athletes can use it.

A British start up, Place Ltd® unveiled the MindRDR® device in 2014, merging a control system

with Google glasses®. This technology detected

brain waves and converted them into commands

for augmented reality using a Neurosky® electro

encephalography biosensor placed on the user’s forehead7. A patent application for electronic contact lenses that display augmented reality

was also made by Google® in 2016. Although

this new device uses nanotechnology to fit inside

the polyethylene terephthalate lens,it can be

used for medical application by examining the

fluids on the cornea’s surface7-8.

The human nose is far more complex than the

ear or the sight, especially when it comes to the

systems that initiate the initial reaction to an

external stimuli. On the other hand, hundreds

of different types of biological receptors are involved in the sense of smell. Electronic noses

have made many interesting advances, but they

still don’t perform as well as our sense of smell

does. Artificial olfaction, utilizing “electronic

noses” consisting of three major components: a

sample handler, multiple gas sensors, and a signal processing technique.

An electronic nose is a machine that is designed

to detect and discriminate among complex

odours using a sensor array.

By making the sound audible, hearing aids

serve to treat hearing loss. The American Society Sonitus Medical® researchers came up with

the idea to use a detachable experimental prosthetic device called Soundbite® 11, mounted at

the level of the dental organs, to transmit sounds

through bone conduction in cases where the patient has a healthy inner ear but abnormalities

of the external auditory duct and/or tympanic

membrane. The receiver is placed on the ear, on

a pair of glasses, or on a jacket pin in order to

record ambient noises.

The SoundBite hearing system is an intraoral device created by Sonitus Medical12. The SoundBite hearing system works on bone conduction, it

may produce sound without the need for a working middle or outer ear. Bypassing the middle

and outer ears completely, the SoundBite hearing device is made to enable sound to pass via

the teeth, bones, and cochleae. The SoundBite is

designed to help people with SSD, conductive,

or mixed hearing loss regain normal hearing

without the need for surgery by employing bone

conduction via the teeth.

The SoundBite hearing system consists of a discrete, detachable in-the-mouth (ITM) device and

a behind-the-ear (BTE) microphone unit that

houses the receiver, wireless transmitter, and attached microphone. The tiny microphone is put

in the affected ear canal, where it is fitted with

an open dome to pick up noises. The SoundBite

hearing device is designed to take advantage

of the patient’s own pinna, or outer ear, which

naturally possesses the ability to capture and

guide sound by placing the microphone in the

ear canal. Following microphone capture, sound

is processed by the BTE digital audio device and

wirelessly sent to the detachable ITM hearing

aid. Through the use of cutting-edge technology,

the ITM gadget produces subtle sound vibrations

that go through the teeth, bone and cochlea.

An innovative low-frequency gadget known as an

audio implant12 was created in 2002, but it was

not removable, the process involved implanting

a sensor to detect noises in the inner ear through

bone conduction in a prosthetic tooth. One advantage was that voices seemed crystal like due

to the ability to detect vibrations below the average apparent frequency.

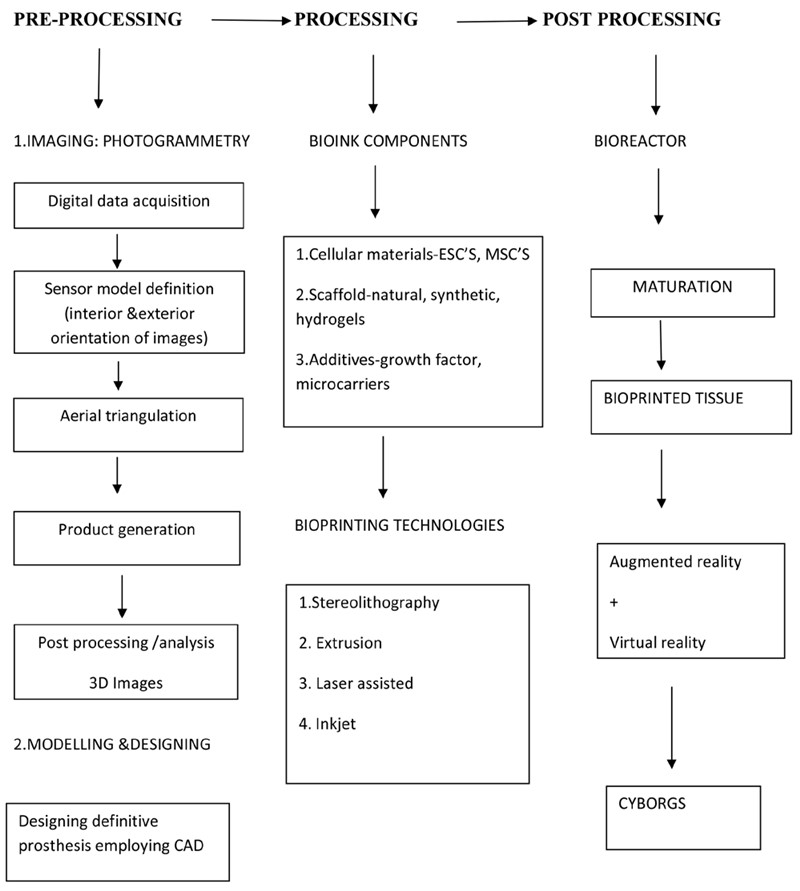

3D bioprinting is the process of printing biomaterials, bioactive factors, and even cells with precise placement and spatial control to recreate

human tissues and organs that closely resemble

their natural counterparts in terms of both structure and function. The technique is based on the

additive manufacturing which is combination of

tissue engineering and 3D printing15. One area

of regenerative medicine called tissue engineering uses patient cells to make autologous grafts.

Murphy and Atala described 3D bioprinting as,

‘‘layer-by-layer precise positioning of biological

materials, biochemicals and living cells, with

spatial control of the placement of functional components (extracellular matrix, cells and

pre-organized microvessels) to fabricate 3D

structures.’’16

A bioink is an integration of either differentiated

cells or stem cells and fluidic biomaterial17. It is

comparable to the cell-containing extracellular

matrix, which forms the scaffold when correctly

deposited and polymerizes or cross-links. As the

technology has advanced, it is now possible to

deposit many components of bioinks with exceptional accuracy, simulating the intricate architecture of human tissues, when previously only

a single bioink could be deposited. The specific

application, the kind of cells, and the bioprinter

to be utilized all influence the choice of bioink.

The current state of bioprinting technology is

insufficiently advanced to draw in the funding

required for proper development and to proceed to meaningful clinical trials. Since the inks

utilized in the technique did not contain any organic components, despite the fact that various

medicinal applications have been described,

they more closely align with the concept of 3D

printing than bioprinting. For instance, implants

used in cranioplasty20 are made especially to

address defects in the bone. The protocol states

that the patient’s tomographic data must be

used to determine the implant form and cutting

guide. A synthetic bone structure created in vitro is then used to fill the patient deficiency. This

procedure has been carried out using printed

hydroxyapatite, polyetherketoneketone (PEKK),

or polycaprolactone (PCL) inks21. Research on

oral bone-mucosa composites for palatal defect

reconstruction has also been done22.Within the

field of maxillofacial reconstruction, the same

3D printing technique proved beneficial for ear

and nose reconstruction23. Instead of using cartilage, printed acrylonitrile/butadiene/styrene

(ABS) scaffolds coated with hydrogel and chondrocytes or secondary coated with fibronectin

for biocompatibility were used to replace the

cartilage. Another group even printed an ear

that could hear noises that a typical human ear

cannot by seeding alginate hydrogel with chondrocytes and combining it with a conductive

electronic antenna24. The nanoelectronic components’ integrated silver nanoparticles allowed

the signals from the cochlea-shaped electrodes

to be read out. This proof-of-concept ear showed enhanced radio frequency reception auditory

perception as well as stereo audio perception.

The procedure utilized to extricate 3D data from

2D objects is called photogrammetry. The data is

procured by taking pictures of target spots that

reflect light, and after that utilizing those photographs to construct a three-dimensional model25.

Utilizing the suitable facilitate frameworks, the

common geometric relationship between the focuses and the picture is computed. This strategy includes taking all of the photographs with

the versatile gadget from different statures and

points, at that point nourishing the data into program to create a 3D model26. Since the mid19th

century, photogrammetry has been utilized for

3D photography, which was developed from radar, polygonal and radiometry. Photogrammetry

enables “Structure from Motion” (SFM), where

software examines the common characteristics

of each image describes and can build a 3D image from overlapping features using a complex

algorithm that minimizes the sum of errors in the

relative displacements of coordinates and reference points. This minimization is called “beam

regularization” and is often performed using the

Levenberg-Marquardt algorithm27.

Collection of Data

The new biotechnological methods promises

a vast array of potential maxillofacial applications, but their entrace on the healthcare market

is still undefined. The human organs are made

up of different cell types, matrices, and complex

configurations within each organ. Currently no

method can produce an entire organ or tissue

because of limitations in biomaterial compatibility, vascularity, resolution, and no defined

regulatory framework for bioprinted constructs.

As technology progresses in the realm of printing, and as more efficient and affordable printing techniques emerge, it’s essential to establish

and maintain quality control standards at every

stage of the process, including during model design, choosing the bioink, verifying the printing,

allowing the bioink to mature after printing, and

evaluating the quality of the final product.

Bioprinting involves a series of steps, each of

which must be carefully coordinated with the

others. Perfusion bioreactors are anticipated to

play a crucial role in the further integration of bioprinting technologies. However, beyond these

future prospects, the most critical aspect will be

the incorporation of bioinks with enhanced bioprintability and biofunctional characteristics.

Currently, the majority of bio-based materials employed in bioprinting are derived from polymers typically used in tissue engineering, and

they often lack the necessary rheological and

crosslinking properties that are essential for a

successful bioprinting process29. Moreover, given that the primary goal of bioprinting is to create

functional tissue constructs, there is also a need

for the development of more advanced assays

capable of evaluating cell functionality within

3D structures. Given the rapid advancement of

bioprinting technology and the widespread interest in this field across various scientific disciplines, it is anticipated that these challenges

can be addressed, leading to the availability of

bioprinted constructs for translational research

and accelerating the drug development process.

Cyborgology modifies maxillofacial prosthesis,

altering the wearer’s body depiction and self-image, resulting in new body sensations and perceptions of their inner selves and surroundings1

.

More research is required to combine bioprinted organic materials with artificial structures to

create a robotic, living entity. In the near future,

beneficiaries of this multidisciplinary approach

may be able to receive transformed tissues and

organs along with better neurophysiological

links to their surroundings. The advancement

of maxillofacial prosthetics for the future needs

constant ethical oversight3

. Unfortunately, the

scientists and engineers tasked with developing

tomorrow’s biotechnologies may not completely

comprehend the implications of their creations

for human evolutionary futures. This goes beyond simply replacing parts; it also includes

restoring sensory capacities, which improve the

brain’s ability to comprehend information.

Digital facial impressions using mobile device

photos enabled monoscopic photogrammetry to

generate 3D models. A less expensive option to

record the facial anatomy of patients using inexpensive free software. This would allow for the creation of physical working models, templates

for facial prostheses, improved patient communication before and during treatment, and increased access to digital clinical solutions for

clinical centers with limited technological resources. Standardizing a photo capture strategy28 for data capture and processing is crucial

since prolonged capture times with multiple images are prone to errors. The capture-to-print

prototype process will be made simpler with a

common photo capture technique.

In the fields of biotechnology and 3D scanning,

extensive research is being conducted which

promises, better future by overcoming challenges. While many of these technologies are in the

developing state, this integrated approach can

revolutionize future maxillofacial rehabilitation.

This review has highlighted the role of various

digital and biotechnologies in overseas maxillofacial prosthetic collaboration as an alternative to the conventional techniques. However,

introduction of new technologies and techniques

would require changes to current treatment protocols, workflow setting and training requirements. These challenges can be broadly considered as technological limitations and expenses.

Advancement in technology has a profound impact on the maxillofacial restoration of form and

function. However, creating indistinguishable

maxillofacial prostheses continues to be a challenge.