Aim - The present investigation was done with

an aim to evaluate and compare the effect of two

chromatogens on color stability of three provisional

materials before and after thermocycling.

Materials and methods - Three commercially

available provisional materials were chosen -

DPI heat cure, Protemp™4 chemical cure and

the relatively newer Luxatemp Solar dual cure

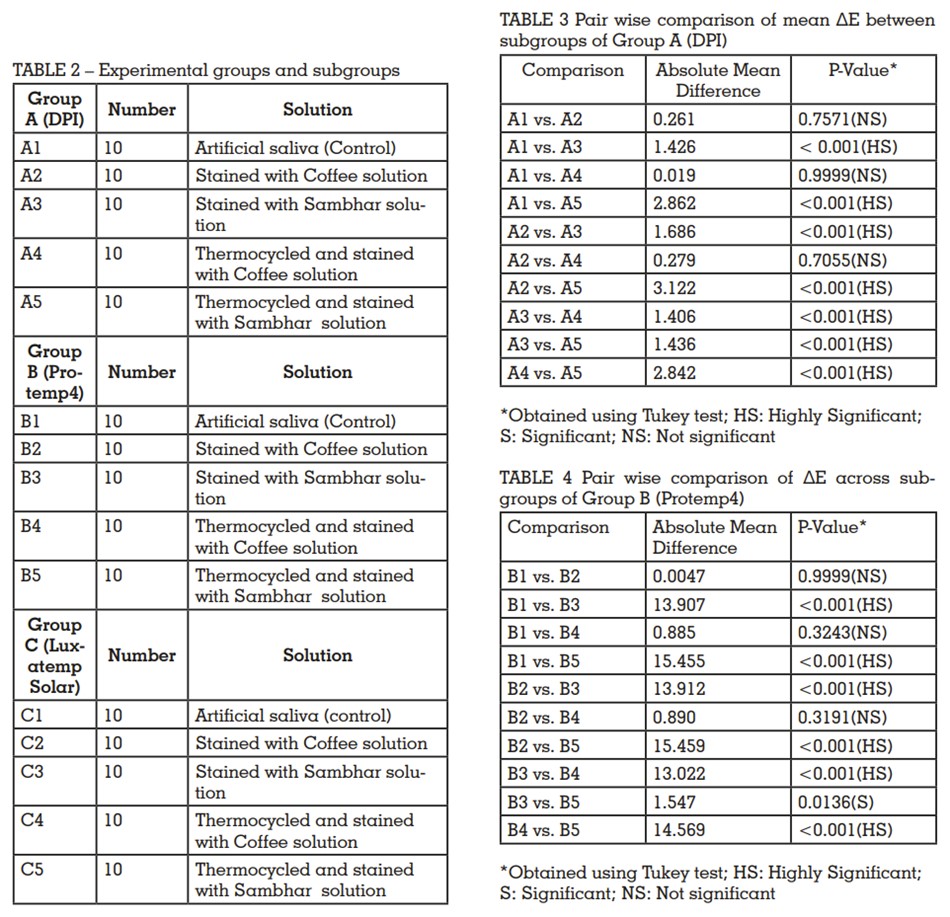

material. Flat circular metallic dies were prepared

of 22 mm diameter and 2 mm thickness. Total 150

samples were prepared from the materials using

these dies. The samples were finished and polished

using standardized methods. They were divided

into five groups. Two groups from each material

were subjected to a standardized thermocycling

regimen. The samples were immersed in two

staining solutions - coffee solution and sambhar

curry solution for 30 days. Artificial saliva was used

for the control group. The solutions were prepared

using a standardized method and were changed

every day. The color measurements were done twice

- once before thermocycling and staining and once

after, in CIE L*a*b* color system using a reflectance

spectrophotometer.

Results – Statistical analysis was done in SPSS version 20.0 using One-way ANOVA and Tukey’s

post-hoc test. p value <0.05 was considered

statistically significant.

Conclusions – New material Luxatemp Solar showed

least color stability, followed by Protemp™4 whereas

DPI showed maximum color stability. Sambhar curry

showed higher staining ability. The color changes

seen with coffee and control were not clinically

perceptible. Thermocycled samples showed more

color change than non thermocycled samples.

Key words: Color stability, provisional materials, coffee solution, sambhar curry solution, thermocycling.

CLINICAL IMPLICATIONS - DPI provisional restorative material showed better color stability than Protemp™4 and Luxatemp Solar. However, the values of color change were clinically acceptable with the control and coffee group for all materials. Hence, patients with a simple or a health conscious diet, or the ones regularly consuming coffee, can be given prosthesis using any provisional material. If the diet of the patient includes typical Indian curries, it is advisable to use DPI heat cure provisional material as it showed clinically acceptable color change with sambhar, which was the representative of Indian curries

Provisional restorations are an essential part

of fixed prosthodontic treatment.1 They are

designed to enhance esthetics, stabilization

and/or function for a limited period of time, after

which they are to be replaced by a definitive

prosthesis.2 These may be required to be placed

in the patients’ mouth for a few days to few

weeks. Occasionally, interim treatment has to

function for extended intervals and provide

long-term tooth protection and stability while

adjunctive treatment is accomplished,3 like in the

midst of the Covid pandemic where most dental

clinics performed only emergency treatments

globally or other emergency situations where

patient cannot report to the clinic. Amongst all its

functions, esthetics of the provisional restoration

is of prime importance especially in cases where

the provisional restorations are going to be used

for a long period of time and or are in the esthetic

zone.4 Discoloration of provisional restorations

may result in patient dissatisfaction and an

additional expense for their replacement5

,

adding to the number of visits and costs.

Regardless of their chemistry, most provisional

restorative materials are subject to sorption,

a process of absorption and adsorption of

liquids. As a result, color changes may occur

over time when these provisional restorations

are subjected to various staining agents.6

Indian food consists of various chromatogenic

substances such as tea, coffee, colas, turmeric

powder, red chilli powder, spices, oil, curry etc.

which are consumed on a daily basis and can

adversely affect the color of the provisional

restorative material.7

With globalization, Indian

food is now relished on a regular basis in most

parts of the world. A number of studies have

investigated the color stability of provisional

materials in various chromatogens. However, the

effect of commonly consumed chromatogens by

the Indian population on provisional restorative

materials has not been studied much.

Intraorally, temperature changes are seen

induced by routine eating and drinking.

Thermocycling can be done to simulate this

clinical situation in the laboratory.8 However,

limited data is available about the color stability

of provisional resins on temperature changes

subjected to thermocycling.

Today, with increased dental awareness

amongst patients and their improved standard

of living, it is imperative for the Prosthodontist

to provide a prosthesis which not only functions

efficiently, but also maintains its appearance

over the entire period of service.

Considering these facts, the present study

was undertaken to evaluate the color changes

that occurred when DPI heat cure, Protemp™4

chemical cure and the relatively newer

Luxatemp Solar dual cure provisional restorative

materials, were subjected to immersion in

coffee and sambhar curry solution, which are

common Indian chromatogens, for a period

of 30 days, before and after thermocycling,

which represented temperature changes

(Table1). The null hypothesis was that there is

no significant difference in the color stability of

tested provisional materials when exposed to

chromatogens or thermocycling.

The details of all materials are given in Table 1. The methodology was divided as follows:

ΔE= [(ΔL)2 + (Δa)2 + (Δb)2]1/2

Values ΔE > 3.7 was considered as clinically not

acceptable.21

The data of the color measurements was

obtained and subjected to statistical analysis.

The analyses were performed using SPSS version

20.0 (SPSS Inc.). The comparison of mean color

stability across groups was performed using

one-way analysis of variance (ANOVA). The pair

wise analysis was performed using Tukey’s post-hoc test. The p value <0.05 was considered as

statistically significant while p value <0.001 was

considered as highly significant.

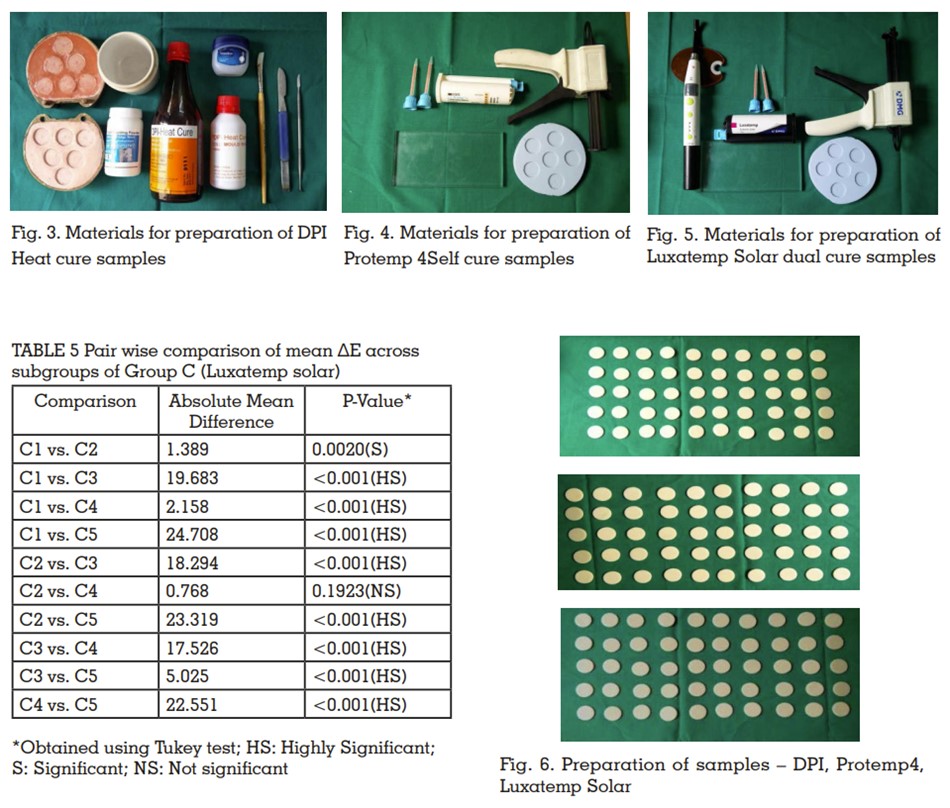

It is evident from the comparison of mean ∆E

for all the materials and treatments per subgroups of DPI, Protemp™4

and Luxatemp Solar

(Graph 1) that for all the groups, the maximum

color change was seen with the thermocycled

samples stained with sambhar curry solution

and minimum discoloration was seen with

control samples and those stained with coffee.

The intragroup analysis showed that for DPI and

Protemp™4 groups, all the paired comparisons

had statistically significant differences of mean

color stability except comparisons between

control samples vs. samples stained with coffee,

controls vs. samples thermocycled and stained

with coffee and samples stained with coffee vs.

samples thermocycled and stained with coffee

(Table 3, 4). For the Luxatemp Solar group, the only non-significant comparison was between

samples stained with coffee vs. samples

thermocycled and stained with coffee, while rest

were statistically significant. (Table 5).

The intergroup analysis showed that in the

comparison of samples of all experimental

subgroups across different materials (Table 6,

Graph 1), the mean for Luxatemp solar samples

was significantly higher than that of other two

treatment groups, as indicated by P-value <

0.001. In control samples, the mean for Protemp

4 was maximum, followed by DPI and then

Luxatemp solar. The difference in the means,

however, was statistically insignificant.

Perceptible color change of the provisional

material may compromise its acceptability. The

provisional restorative materials chosen were

commonly used ones, with the exception of

Luxatemp Solar dual cure material, a relatively

new material with very limited references in

literature as regards stain resistance.

The spectrophotometer used in this study

provided large area view i.e. a 25.4 mm port

size that had a 22 mm view area for the color

measurement of a sample. Hence, 22 mm

diameter was selected as the size of the samples.

Thickness of 2 mm was selected as it is generally

the maximum facial or occlusal thickness of

a provisional crown and it also allowed ease

of manipulation and polishing.19 Crispin and

Caputo23 found that the color of specimens with

rough surfaces significantly changed. In order

to standardize the procedures, the samples were

finished using coarse pumice as it is routinely

used in clinics for polishing of the restorations.24

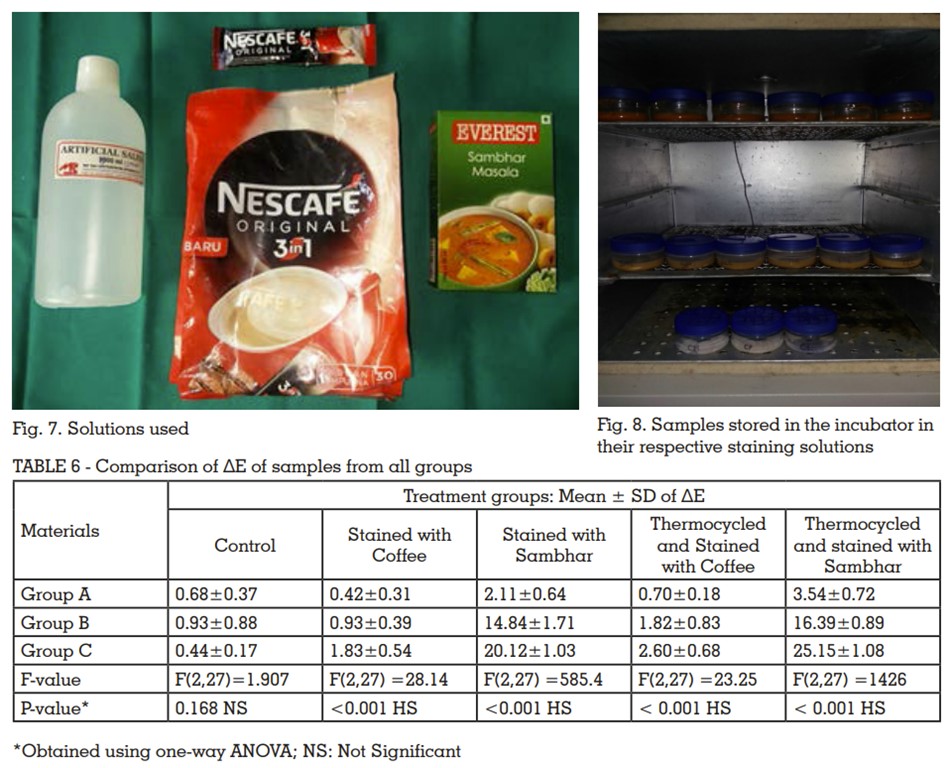

The staining solutions, namely coffee solution

and sambhar curry solution were those which are

commonly consumed by the Indian population

and those that have strong potential of staining. Both solutions were prepared in a standardized,

quantifiable manner. The sambhar solution

is a curry that contains most of the Indian

chromatogenic spices that are added in the

food routinely like turmeric powder and red

chili powder.7 It also contains a mixture of many

Indian spices used – coriander, cumin, Bengal

gram, black gram, pigeon pea, fenugreek,

rice, common salt, curry leaf, tamarind, cassia

and asafoetida, all of which have staining

properties. This solution was the representative

liquid of Indian food having multiple spices and

condiments added and it showed the maximum

discoloration in all the materials. Gupta25 stated

that the yellow-orange color of turmeric is due

to a conjugated diarylhepnoid like Curcumin

(3%), which is an active substance, also known

as Natural Yellow. The uptake of this colorant by

the resins causes staining. Munde and Radke7

found that sambhar curry solution has the highest

staining potential, followed by tea solution

and then tobacco solution. The combination

of various strong chromatogens and spices in

sambhar, commonly found in Indian curries,

could be the reason for the highly significant

discoloration produced by this solution.

Guler et al12 has shown that the addition of the

sugar and milk powder in beverages results

in increased color change and the differences

were found to be significant. In the present

investigation, pre weighed, commercially

available sachets were used as it contained

coffee, sugar and milk powder in fixed amounts

for standardisation. The coffee solution showed

less discoloration compared to sambhar curry

solution and the discoloration caused was

clinically acceptable (ΔE < 3.7). Chan, Fuller

and Hormati26 found that coffee caused more

discoloration than tea and cola beverages.

In contrast to these findings, Um and Ruyter27

reported that tea caused more discoloration than

coffee after 48 hours of storage. Absorption and

penetration of colorants into the organic phase

of the resin-based material is probably due to compatibility of the polymer phase with the yellow

colorants of coffee. Smaller molecular size of

coffee coupled with the absorption phenomenon

is said to be the cause of the staining potential

of coffee.20 Coffee also contains large amounts

of staining agent like gallic acid which could be

another reason for its staining capacity.28

The solutions were diluted with artificial saliva

with a ratio of 1:26,17 and stored at 37ºC in a

thermostatically controlled incubator to simulate

intra oral environment.18,19 Samples of the control

group were dipped in commercially available

artificial saliva as provisional restorations

are bathed in saliva in the mouth. This group

also represented the population whose diet

was simple and did not include coffee or

curries. Discoloration produced by this group

was clinically not perceptible (ΔE < 3.7) and

intergroup comparisons were non-significant.

Thermal stress may affect the surface and

structural integrities of resin materials and

render the restorations more susceptible to

staining and discoloration.14 In the present

study, thermocycled samples showed more

discoloration than the non-thermocycled ones

in all the three material groups. The results may

be explained by Strohaver and Mattie 28 who

stated that thermal energy, being sufficiently

capable of causing decomposition of the organic

components present in the resins, leads to the

significant chromatic changes after thermal

cycling. Thermocycling promotes volumetric

contraction and expansion of materials, leading

to degradation. Oliveira et al15 found that

thermocycling increased the surface roughness

in most resins, which may also be the cause of

increased discoloration seen with thermocycled

samples in the present study.

Chemical discoloration has been attributed

to the oxidation of polymer matrix or oxidation

of unreacted double bonds in the residual

monomers and subsequent formation of degradation products from water diffusion.27 In

the present study, methyl methacrylate material

(DPI) was more color stable than the bisacryl

composite materials (Protemp™4 and Luxatemp

Solar). According to Haselton, Diaz-Arnold and

Dawson6, bis-acryl resins showed lesser color

stability as compared to polymethyl methacrylate

(PMMA) since bis-acryl polymers are more polar

than PMMA polymers and therefore have greater

affinity towards water and other polar liquids.

Yannikakis et al30 found that composite based

resins can absorb water at a higher rate because

of the high diffusion coefficient in comparison to

methyl methacrylate. Hence, the present study is

in agreement with these studies.

Strohaver and Mattie 28 showed that the degree of

polymerization is critical to clinical performance

of any resin system and that the degree of

polymerization is not only dependent on type of

resin used, but also the method of polymerization.

They also found fewer voids in heat cure

specimens than in self cured and light cured

specimens. The use of heat for curing produced

a higher degree of polymerization. Khokar et

al31 found that air voids in the resin material

may lead to inhibition zones of unpolymerized

material, resulting in lower color stability. This

may be the reason of the lower color stability of

dual cure (Luxatemp Solar) and chemical cure

(Protemp™4) provisional materials as compared

to the heat cure provisional resin (DPI).

The color stability of the tested provisional

restorative material thus depends on the

chemical composition of that material, the type

of polymerisation and the environment it is

subjected to.

Within the limitations of the study, following conclusions can be drawn: