In an abutment - implant fracture, it is generally a challenge for the clinician to remove the fractured fragments. A fractured abutment screw of a single crown or fixed dental prostheses supported by an endosseous implant is a complication. In some cases, the screw cannot be removed, and alternative solutions should be considered. This clinical report describes a fractured abutment screw prostheses and cold welded screw, which was impossible to retrieve.

Key words: Dental implant, Implant abutment screw fracture, over load, Implant abutment screw retrieval

Dental implants are an effective, reliable, and

predictable prosthodontic treatment option for

partially and completely edentulous patients.1,2

Despite a high success rate of 97% to 99%,3,4

technical and biological problems may be

encountered. Biological complications include

peri-implant radiolucencies, peri-implantitis, and

radiographic signs of loss of osseointegration.

Technical complications include loss of retention,

screw loosening, and fractures of porcelain/framework/screws.5

Abutment screw fracture is an uncommon (range

from 0.5% to 8%)6

but challenging the technical

complication in implant-retained restorations

and may occur due to bruxism, unfavorable

superstructure, overloading, malfunction,

premature occlusal contacts, metal fatigue after

screw loosening, and component misfit.6-9

Dental implants have been a life enhancing

modality for partially and completely edentulous

patients. Implants can successfully support a

cemented or screw retained single crown. However,

this modality is not without complications. A

fractured abutment screw may occur after the

prosthesis is under functional cyclic loading. The

abutment screw may be overloaded and fracture

leaving the abutment and coronal screw fragment

inside the abutment/crown and the apical fragment

in the fixture itself. Abutment screw fracture is a

rare event, occurring less than 0.5 %.10

Occlusal loading is a multi-directional and variable

magnitude force. Even though an integrated

implant transmits the load to the surrounding

bone, the load is transmitted through the abutment

and its retaining screw. The abutment screw will receive tensile and bending moments that can

induce a fatigue fracture.10, 11

There are several techniques for managing a

fractured abutment screw. These include removal

and retreatment of screw and prostheses, followed

by re-fabrication, screw fragment retrieval and

other techniques.12,13 Many but not all implant

companies offer fracture screw removal kits

but they are expensive and do not consistently

remove the fracture segment. Case reports and

a technique for abutment, fragment retrieval and

crown-abutment separation and re-cementation

of the crown and over-denture retainer fracture

are discussed herein.

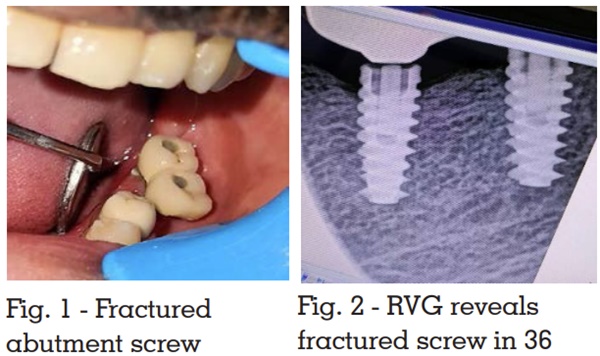

A 25 year old male patient reported to the

Department of Prosthodontics, with the chief

complaint of loosening of implant crown prostheses in lower posterior region. Past dental history

revealed that patient had undergone implant

placement in lower left back tooth region 3 years

before with screw retained prostheses. On intraoral

examination, there was a fractured abutment

screw in 36 region and screw loosening in 37 region

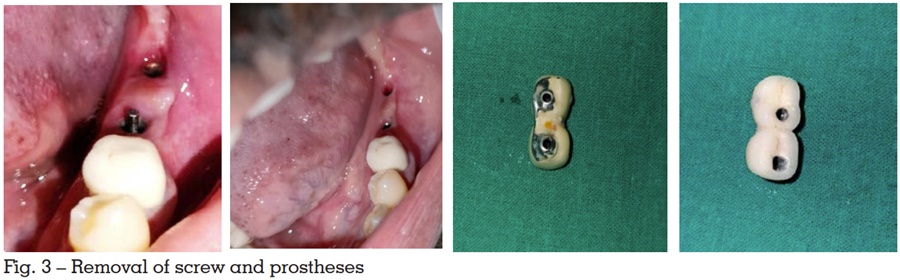

(Fig 1). RVG revealed fractured implant abutment

screw in 36 region with well osseointegrated

implant (Fig 2).

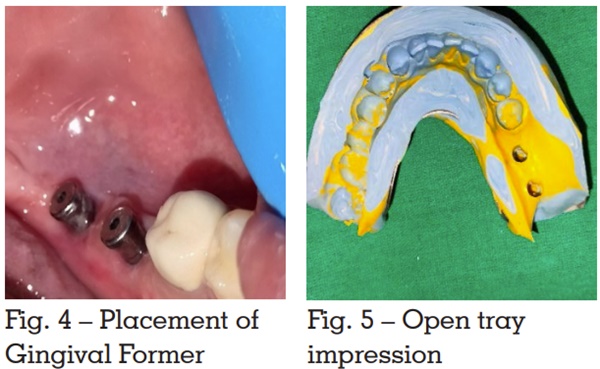

The screw retained crown prostheses is removed

and the fractured screw was removed by using

ultrasonic scaller tip. (Fig 3)

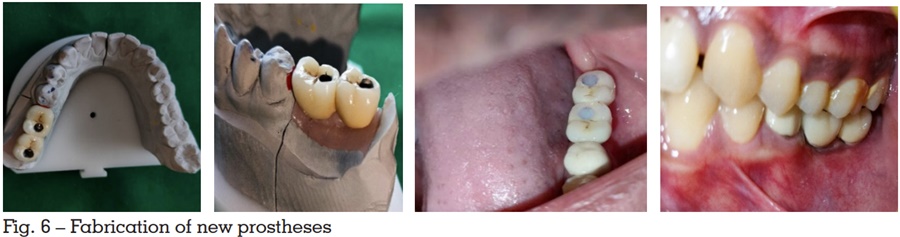

After the removal of prostheses, gingival former

was placed on 36 and 37 region to guide the

healing of soft tissue. (Fig 4).

Impression copings was placed and closed tray

impression were made for the fabrication of new

abutment screw with the same existing crown

prostheses (Fig 5).

The new screw retained prostheses was fabricated

with the existing crown and the fit was checked

intraorally along with occlusion (Fig 6). The access

hole of final screw retained prosthesis was filled

with putty material and flowable composite

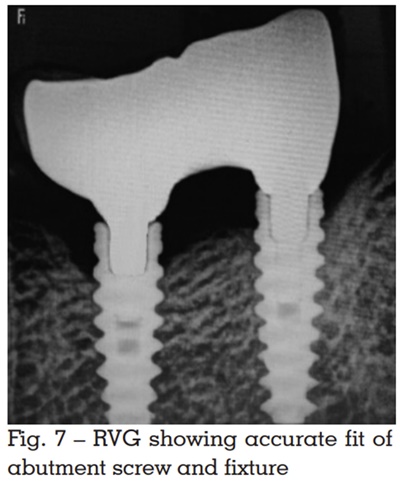

resin. RVG is made to check the accurate fit of

the abutment screw and implant fixture (Fig 7).

A common complication of implant prosthetics is

with components. The abutment screw connects

the abutment to the fixture and can fracture

under occlusal functional load. In preparation

for treatment of a patient presenting with an

abutment screw fracture, a radiograph should be taken to insure osseous support quality of

the supporting implant. In this case report, the

fractured implant abutment screw is managed by

use of simple method by using ultrasonic scaler tip.

The conservative approach in the management of

abutment screw fractures is to retrieve the fractured

screw to facilitate the reuse of the implant. When

an abutment screw fractures above the implant

body, the fractured screw is grasped with a

hemostat, or a sharp explorer is used to remove

it with a counter clockwise motion.14,15 If the

abutment screw fracture occurs within the body

of the implant, retrieving the screw fragment will

be more challenging. A modified spoon excavator

can be used to engage the fractured screw after

making a groove on it. The working end of the

spoon excavator is cut perpendicularly to engage

the groove on the fractured fragment.

Although clinicians can use various techniques

to remove fractured abutment screws, every

effort should be made to eliminate the cause

of screw fracture. Conservative techniques are

to be advocated initially before considering

the use of commercial retrieval kits. Retrieval

of the broken screw fragment should be done

judiciously to prevent any internal damage to the

implant structure. More clinical research should

be conducted to determine the effectiveness of

various techniques in the retrieval of fractured

abutment screws.